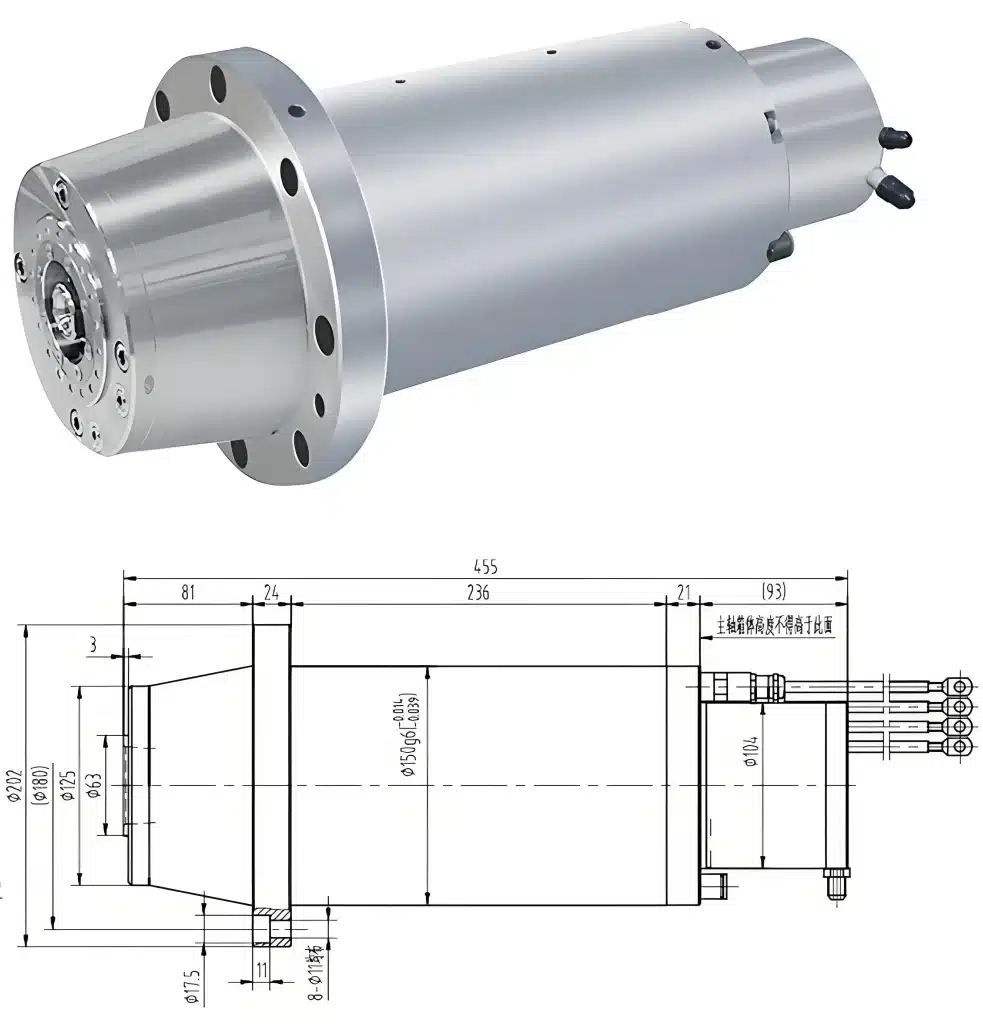

A2005151 High-Torque Dual-Winding Spindle for Mitsubishi CNC Systems

BBT40 | 48 N·m Torque | Center-Through Coolant | Optimized for Heavy-Duty Gantry & Large VMCs

The A2005151 is an ultra-high-torque, large-format electric spindle engineered for the most demanding heavy-duty milling applications on gantry machining centers, large vertical machining centers (VMCs), and boring mills. With a substantial 150mm flange and a robust BBT40 tool interface, it delivers an extraordinary 48 N·m of torque in Y-connection and 11 kW of power in Δ-connection. Featuring an integrated center-through coolant system (7 MPa) and full compatibility with Mitsubishi CNC and drive systems, it is purpose-built for high-productivity machining of steels, castings, and difficult alloys.

Technical Overview

Designed as a powerhouse for large-part manufacturing, the A2005151 prioritizes immense cutting force, exceptional structural rigidity, and advanced cooling. Its dual-winding motor (Y/Δ) provides operational flexibility, allowing the same spindle to excel in both high-torque roughing and higher-speed finishing. Pre-configured with a Mitsubishi serial encoder, it guarantees plug-and-play performance and optimal servo control within the Mitsubishi ecosystem for maximum reliability.

Core Performance Advantages

- Extreme Torque for Heavy Roughing: In Star (Y) connection, it generates a massive 48 N·m of rated torque at 9 kW, making it ideal for aggressive roughing, deep slotting, and face milling of hardened steels, stainless steels, and heavy castings.

- High-Power Mode for Versatility: In Delta (Δ) connection, it delivers 11 kW of full power and 18.4 N·m torque, suitable for efficient semi-finishing, contour milling, and machining at higher speeds.

- Exceptional Rigidity & Stability: Ultra-high radial stiffness (750 N/µm) and axial stiffness (250 N/µm) create an immensely stable platform, minimizing deflection and vibration to ensure accuracy and surface finish integrity under extreme loads.

- Integrated Center-Through Coolant (CTC): High-pressure coolant delivery (7 MPa maximum) directly through the tool and spindle enhances chip evacuation, reduces cutting zone temperature, and is critical for deep-hole drilling and milling operations.

- Certified Mitsubishi Compatibility: Equipped with a Mitsubishi serial encoder (GEL 2444M) and validated for M800/M80/E80/C80 series CNC and MDS-D/E/EM/EJ/EMH-SP series drives, ensuring seamless integration, simplified setup, and reliable, high-performance operation.

- Robust Toolholding & Sealing: Features a BBT40 tool holder with very high drawbar force (8000 ± 1000 N) and comprehensive air-seal/purge functions to ensure tool security and protect internal bearings from contamination.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Spindle Designation | Electric Spindle |

| Model | A2005151 | |

| Tool Holder | BBT40 (Flange Type) | |

| Bearing Specification | 71910 × 2, 71913 × 4 | |

| Lubrication | Grease | |

| Mounting Orientation | Vertical | |

| Drive Method | Built-in Motor | |

| CNC System Compatibility | Mitsubishi M800/M80/E80/C80 | |

| Drive Compatibility | Mitsubishi MDS-E/EH/EJ/EM/EMH-SP Series | |

| Encoder Signal | Mitsubishi Serial (GEL 2444M) | |

| Tool Change Signal | PNP / NO | |

| Dynamic Balance Grade | G0.4 | |

| Warranty | 1 Year | |

| Spindle Net Weight | 55 kg | |

| Packing Weight (Wooden Case) | 7 kg | |

| Performance | Maximum Speed | 16,000 rpm |

| Radial Stiffness | 750 N/μm | |

| Axial Stiffness | 250 N/μm | |

| Taper Runout | ≤ 2.0 μm (at 25mm); ≤ 8.0 μm (at 300mm) | |

| Face Runout | ≤ 2.0 μm | |

| Rated Power (Star-Y / Delta-Δ) | 9 kW / 11 kW | |

| Rated Torque (Star-Y / Delta-Δ) | 48 N·m / 18.4 N·m | |

| Drawbar Force | 8000 ± 1000 N | |

| Cooling & Auxiliary Functions | Main Cooling Method | Oil/Water Coolant Flow >10 L/min, Cooling Power >1.5 kW, Max. Inlet Temp. 30°C |

| TSC Max. Pressure (Center Through-Tool) | 7 MPa | |

| Tool Coolant Max. Pressure (Ring Spray) | 7 bar | |

| Air Seal Pressure | 2 – 7 bar | |

| Taper Clean Air Pressure | 2 – 7 bar | |

| Tool Release Oil Pressure | 5 – 7 MPa |

Primary Applications

This spindle is engineered for large-scale, high-power machining, including:

- Heavy-duty roughing and milling on gantry and floor-type boring mills.

- Large mold and die manufacturing, especially for automotive and heavy machinery.

- Machining of large structural components in the energy, aerospace, and marine industries.

- Deep cavity milling and high-efficiency face milling operations.

Value Proposition

The A2005151 is the definitive solution for shops that require uncompromising power and rigidity. It transforms large machine tools into highly productive systems by enabling dramatically faster material removal rates while ensuring part accuracy through superior stiffness and thermal control. Its dual-winding design and dedicated Mitsubishi integration offer both versatility and reliability for the most challenging industrial applications.

Power Your Largest and Toughest Projects. Contact our engineering team today to discuss the integration of the A2005151 High-Torque Spindle into your Mitsubishi-controlled gantry or large VMC.