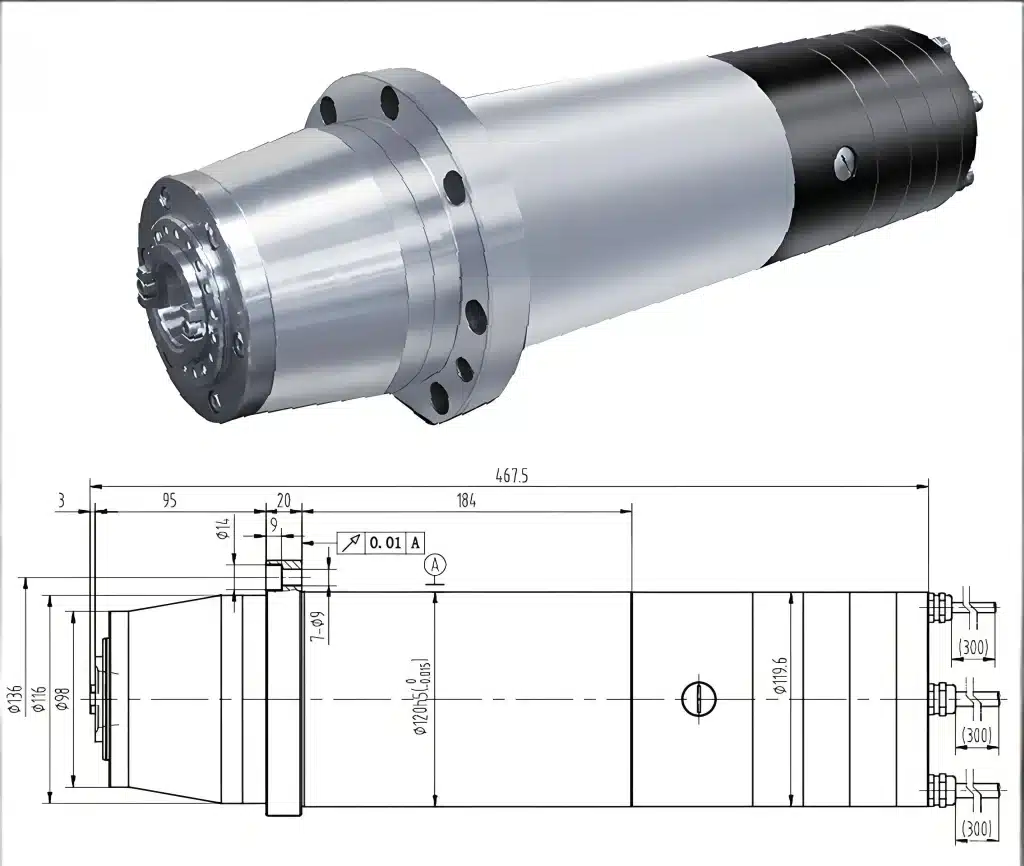

A2005751 High-Torque / High-Speed Dual-Mode Spindle for Mitsubishi Systems

Flexible Power: 16 N·m Torque or 27,000 rpm Speed in One Robust 120mm Package

The A2005751 is a versatile, high-performance electric spindle engineered for seamless integration with Mitsubishi CNC systems. Its unique design offers two distinct operational modes through Y/Δ connection, allowing it to function as either an ultra-high torque powerhouse (16 N·m) or a high-speed spindle (27,000 rpm). This flexibility, combined with exceptional rigidity, makes it an ideal, future-proof solution for demanding milling centers that handle diverse materials and machining strategies.

Product Overview

Built with a robust 120mm outer diameter, the A2005751 delivers reliable power and precision for heavy-duty machining. Its core innovation lies in the configurable motor winding, enabling users to prioritize immense cutting force for tough materials or higher rotational speed for efficiency. Pre-configured for compatibility with Mitsubishi M800/M80/E80/C80 series CNCs and corresponding drives, it ensures plug-and-play performance and operational stability.

Key Features & Advantages

- Dual-Mode Flexibility (Key Differentiator):

- Y-Connection: Delivers 16 N·m of rated torque for extreme heavy-duty roughing, milling of hard metals, and deep-cavity machining.

- Δ-Connection: Provides 8.1 N·m torque and full 7.5 kW power up to 27,000 rpm, optimized for high-speed finishing and semi-finishing operations.

- Optimized for Mitsubishi Integration: Equipped with a Mitsubishi serial encoder (GEL 2444M) and designed for MDS-E/EH/EJ/EM/EMI-SP series drives, ensuring reliable communication, simplified setup, and stable servo performance.

- Exceptional Structural Rigidity: High axial (105 N/µm) and radial (210 N/µm) stiffness provide superior stability, minimize vibration, and ensure accuracy during aggressive cuts.

- Heavy-Duty Build & Automation Ready: Features a robust bearing system (7007×2 / 71910×4), a BBT30 tool holder, high drawbar force (2500-3000N), and PNP/NO signals for reliable automated tool changes.

- Effective Thermal Management: Requires a dedicated oil/water cooling system (>6 L/min) to maintain precision and protect components during continuous high-power operation.

Detailed Technical Specifications

| Category | Parameter | Specification / Configurable Option |

|---|---|---|

| General | Model | A2005751 |

| Mounting Orientation | Vertical | |

| Quality Warranty | 1 Year | |

| Spindle Weight | 26 kg | |

| Performance | Maximum Speed | 27,000 rpm |

| Rated Power / Torque (Δ Connection) | 7.5 kW / 8.1 N·m | |

| Rated Power / Torque (Y Connection) | 11 kW / 16 N·m | |

| Radial Stiffness | 210 N/µm | |

| Axial Stiffness | 105 N/µm | |

| Taper Runout | ≤ 2.0 µm @25mm; ≤ 8.0 µm @250mm | |

| Dynamic Balance Grade | G0.4 | |

| Mechanical & Tooling | Tool Holder | BBT30 |

| Drawbar Force | 2500 – 3000 N | |

| Bearing Specification | 7007 × 2, 71910 × 4 | |

| Lubrication | Grease | |

| System Integration (Configurable) | Cooling Method | Configurable: Oil Coolant or Water Coolant Flow > 6 L/min, Chiller Temp = Ambient + (0~2)°C |

| CNC System Compatibility | M800, M80, E80, C80, etc. | |

| Drive Compatibility | Mitsubishi MDS-E/EH/EJ/EM/EMH-SP Series | |

| Encoder Signal | Mitsubishi Serial (e.g., GEL 2444M) | |

| Tool Change Signal | PNP / NO (Normally Open) | |

| Pneumatic Requirements | Air Seal Pressure | 2 – 7 bar |

| Clean Air Pressure | 2 – 7 bar | |

| Tool Release Pressure | 5 – 7 bar | |

| Tool Release Air Volume | 174 cm³ |

Typical Applications

- Heavy-Duty Mode (Y-Connection): Roughing of hardened steels, titanium alloys, and deep pocket milling in mold manufacturing.

- High-Speed Mode (Δ-Connection): High-efficiency machining of aluminum, finishing operations, and detailed 3D contouring.

- Ideal for job shops and production facilities using Mitsubishi controls that require one spindle to handle a wide range of materials and operations.

Value Proposition

The A2005751 eliminates the compromise between torque and speed for Mitsubishi users. It offers the adaptability of two spindles in one, reducing machine downtime for changeovers and providing a cost-effective solution to expand your machining capabilities. Its certified compatibility guarantees performance and simplifies integration.

Choose Your Mode of Power. Contact us to configure your A2005751 spindle for either maximum torque or high-speed performance, perfectly tailored to your Mitsubishi-based machining center.