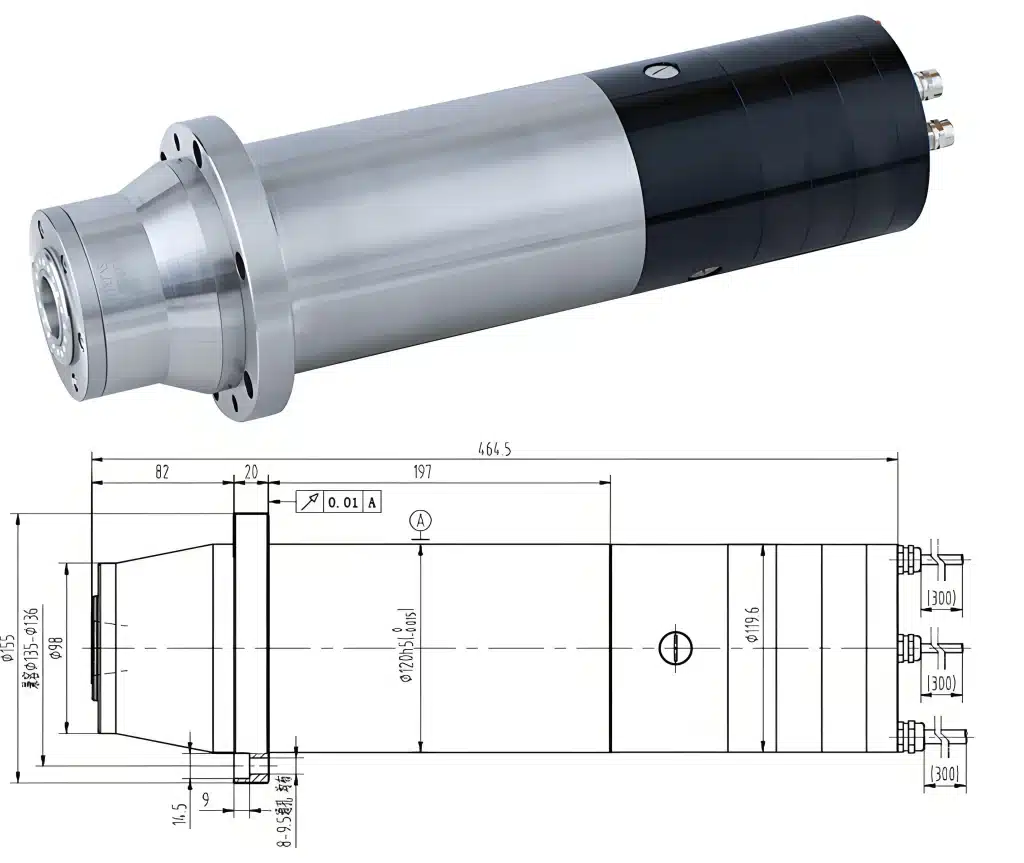

A2004621 High-Performance Dual-Mode Spindle for Mitsubishi CNC with Through-Spindle Coolant

HSK-E40 | 120mm Flange | Y/Δ Dual-Power Modes | Integrated Coolant Through Spindle

The A2004621 is a premium, multi-function electric spindle engineered for ultimate versatility and performance on machining centers equipped with Mitsubishi CNC systems. Featuring a robust 120mm diameter flange, HSK-E40 tool interface, and the unique Y/Δ dual-winding configuration, it seamlessly switches between high-torque and high-speed operational modes. The integrated Through-Spindle Coolant (TSC) system and comprehensive air/oil-mist options make it a complete machining solution for demanding applications, from deep cavity milling to high-efficiency finishing.

Product Overview

Designed as a ready-to-install core component, the A2004621 offers plug-and-play compatibility with Mitsubishi M800/M80/E80/C80 series controls and MDS drive families. Its core innovation lies in providing two distinct performance profiles from a single unit, allowing one spindle to tackle a vast range of materials and operations—from aggressive roughing with high torque to rapid material removal at high speeds. The built-in TSC significantly enhances tool life and chip evacuation in deep drilling and milling operations.

Core Features & Technological Advantages

- Dual-Mode Operational Flexibility (Key Benefit):

- Star (Y) Connection: Delivers higher torque (8.73 N·m) at 5.5 kW, optimized for heavy-duty cutting, milling of hard materials (steel, titanium), and stable machining at lower speeds.

- Delta (Δ) Connection: Provides full 7.5 kW power up to 30,000 rpm with 4.78 N·m torque, ideal for high-speed machining of aluminum, composites, and detailed finishing.

- Integrated Through-Spindle Coolant (TSC): Supports high-pressure coolant delivery (up to 5 MPa) directly through the tool, dramatically improving chip evacuation, reducing thermal load on the cutting edge, and enabling efficient deep-hole drilling and milling.

- Optimized for Mitsubishi Ecosystem: Pre-equipped with a Mitsubishi serial encoder (GEL 2444M) and configured for specific drive software (BND-1501W202, ver. B2+), guaranteeing flawless communication, simplified setup, and reliable servo performance.

- High Rigidity & Precision: Excellent axial (80 N/µm) and radial (160 N/µm) stiffness ensure stability during heavy cuts. Precision ground taper maintains minimal runout (≤2.0 µm @ 25mm) for superior accuracy.

- Robust Tool Clamping & Sealing: Extremely high drawbar force (6000 ± 1000 N) ensures secure HSK-E40 tool holding. Multi-stage air seal and purge functions protect internal bearings from contamination.

- Comprehensive Cooling/Lubrication Options: Supports external oil/water jacket cooling (>6 L/min) and offers configurable central air blow and oil-mist lubrication (2-7 bar) for versatile process adaptation.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Spindle Designation | Motorized Spindle |

| Model | A2004621 | |

| Mounting Orientation | Vertical | |

| Tool Holder | HSK-E40 | |

| Warranty | 1 Year | |

| Performance | Maximum Speed | 30,000 rpm |

| Rated Power / Torque (Star-Y) | 5.5 kW / 8.73 N·m | |

| Rated Power / Torque (Delta-Δ) | 7.5 kW / 4.78 N·m | |

| Radial Stiffness | 160 N/µm | |

| Axial Stiffness | 80 N/µm | |

| Taper Runout | ≤ 2.0 µm @ 25mm; ≤ 5.0 µm @ 150mm | |

| Dynamic Balance Grade | G0.4 | |

| Drawbar Force | 6000 ± 1000 N | |

| Mechanical & Construction | Bearing Specification | 7007 × 2, 7008 × 2 |

| Lubrication | Grease | |

| Spindle Weight | 22 kg | |

| System Integration | CNC System Compatibility | Mitsubishi M800, M80, E80, C80 |

| Drive Compatibility | Mitsubishi MDS-E/EH/EJ/EM/EMH-SP Series | |

| Encoder Signal | Mitsubishi Serial (GEL 2444M) | |

| Tool Change Signal | PNP / NO (Normally Open) | |

| Special Feature | Flange Mount, Two-Speed Winding, Through-Spindle Coolant | |

| Cooling & Pneumatics | Cooling Method | Oil or Water Coolant (Configurable) Flow > 6 L/min, Cooling Power > 1 kW, Max. Inlet Temp 30°C |

| Air Seal Pressure | 2 – 7 bar | |

| Tool Release Pressure | 5 – 7 MPa | |

| Tool Clamp Air Pressure | 4 – 7 bar | |

| Through-Spindle Coolant (TSC) Pressure | Max. 5 MPa | |

| Air Blow Pressure | 2 – 7 bar | |

| Oil-Mist Pressure | 2 – 7 bar |

Primary Applications

This spindle is the ideal choice for complex and varied production environments, particularly suited for:

- Mold & Die Manufacturing: Deep cavity milling (using TSC), roughing of hard steels (Y-mode), and high-speed finishing of electrodes (Δ-mode).

- Aerospace & Automotive: Machining of structural components from aluminum alloys (Δ-mode) and titanium/steel parts (Y-mode).

- Deep Hole Drilling & Tapping: Operations that significantly benefit from high-pressure through-tool coolant.

- Job Shops & Multi-Task Facilities: Where a single, adaptable spindle reduces changeover time and handles diverse customer materials.

Value Proposition

The A2004621 is more than a spindle; it is a highly integrated machining system core. It provides unmatched flexibility through its dual-power modes, enhances capability with TSC, and guarantees reliability through dedicated Mitsubishi system integration. This solution maximizes your machine’s uptime, range, and productivity.

Configure Your Ultimate Machining Solution. Contact our engineering team to specify your A2004621 spindle’s operational preferences and integrate this versatile powerhouse into your Mitsubishi-based machining center.