A2001901 High-Performance Dual-Mode Spindle for Mitsubishi CNC Systems

BBT30 Tool System | Y/Δ Dual-Power Configuration | Mitsubishi Optimized

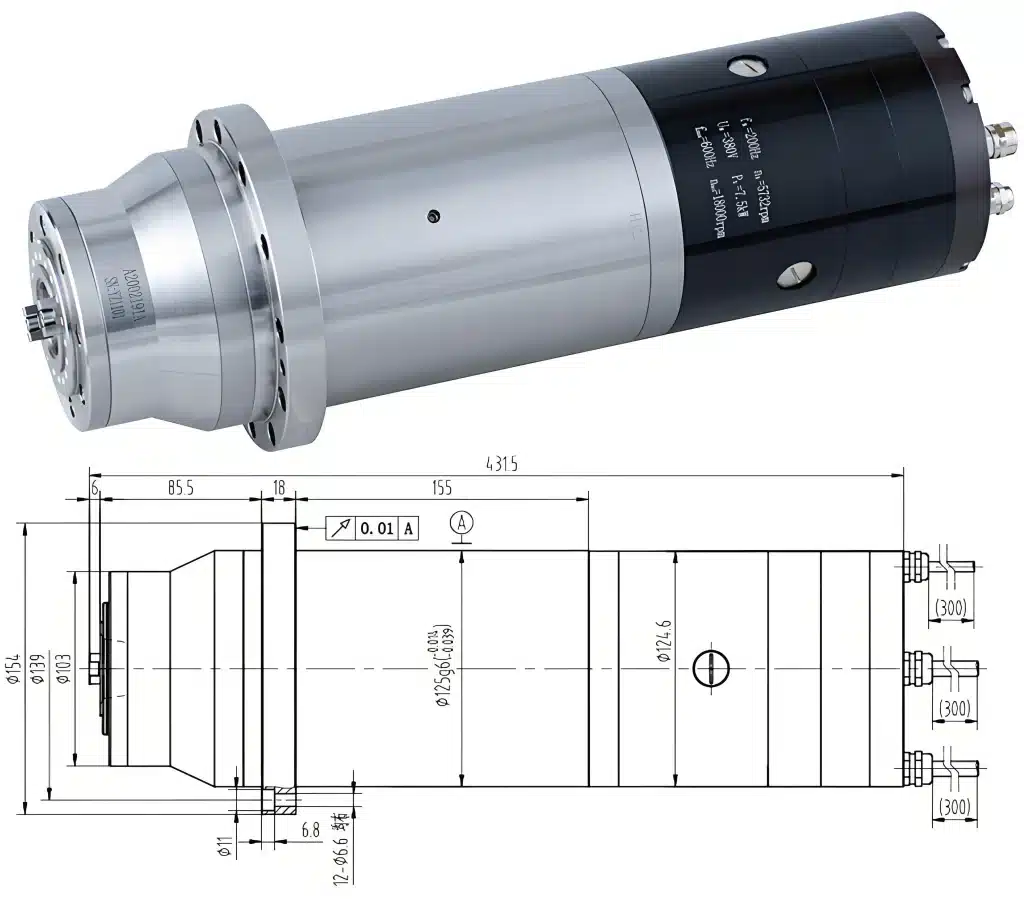

The A2001901 is a precision-engineered electric spindle designed for seamless integration with Mitsubishi CNC systems, offering versatile high-performance in a robust 125mm package. Its defining feature is the Y/Δ dual-winding configuration, allowing operators to select between a high-torque mode for demanding materials or a high-power, high-speed mode for efficient machining. Pre-configured for plug-and-play compatibility, it delivers reliability and flexibility for modern machining centers.

Technical Overview

Built with a focus on rigidity and thermal stability, the A2001901 is ideal for a wide range of milling applications. The star (Y) connection prioritizes torque for challenging cuts, while the delta (Δ) connection unlocks full power at higher speeds. This adaptability, combined with dedicated Mitsubishi communication interfaces, makes it a future-proof core component for job shops and production environments utilizing Mitsubishi controls.

Core Features & Advantages

- Dual-Mode Operational Flexibility:

- Star (Y) Connection: Delivers 10.9 N·m of high torque at 5.5 kW, optimized for stable machining of steels, stainless steels, and difficult-to-machine alloys.

- Delta (Δ) Connection: Provides 7.5 kW of full power up to 27,000 rpm, ideal for high-speed milling of aluminum, composites, and detailed finishing operations.

- Certified Mitsubishi Compatibility: Equipped with a Mitsubishi serial encoder (GEL 2444M) and validated for use with M800/M80/E80/C80 series CNC and MDS-E/EH/EJ/EM/EMI-SP series drives. This ensures reliable performance, simplified setup, and stable servo control.

- Exceptional Rigidity for Accuracy: High radial stiffness (300 N/µm) and axial stiffness (100 N/µm) provide a solid foundation, minimizing deflection and vibration to ensure superior part accuracy and surface finish.

- Robust & Reliable Construction: Features a heavy-duty bearing system (7008×2 / 71910×3) with grease lubrication and a BBT30 tool holder with substantial drawbar force (2000-2600 N) for secure tool clamping.

- Effective Thermal Management: Requires an external oil or water cooling system (>6 L/min) to maintain consistent precision and protect components during extended, high-power operation.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General & Ordering | Spindle Designation | Motorized Spindle |

| Model | A2001901 | |

| Mounting Orientation | Vertical | |

| Spindle Diameter | 125 mm | |

| Tool Holder | BBT30 | |

| Warranty | 1 Year | |

| Performance | Maximum Speed | 27,000 rpm |

| Rated Power / Torque (Star-Y) | 5.5 kW / 10.9 N·m | |

| Rated Power / Torque (Delta-Δ) | 7.5 kW / 4.8 N·m | |

| Radial Stiffness | 300 N/µm | |

| Axial Stiffness | 100 N/µm | |

| Taper Runout | ≤ 2.0 µm (at 25mm); ≤ 8.0 µm (at 250mm) | |

| Dynamic Balance Grade | G0.4 | |

| Drawbar Force | 2000 – 2600 N | |

| Mechanical Construction | Bearing Specification | 7008 × 2, 71910 × 3 |

| Lubrication | Grease | |

| Spindle Weight | 25 kg (Packed: 32 kg) | |

| Drive Method | Built-in Motor | |

| System Integration | CNC System Compatibility | Mitsubishi M800, M80, E80, C80 |

| Drive Compatibility | Mitsubishi MDS-E/EH/EJ/EM/EMH-SP Series | |

| Encoder Signal | Mitsubishi Serial (GEL 2444M) | |

| Tool Change Signal | PNP / NO (Normally Open) | |

| Drive Software Code | BND-1501W202 | |

| Drive Software Version | B2 or above | |

| Cooling & Pneumatics | Cooling Method | Oil or Water Coolant Flow > 6 L/min, Max. Inlet Temp 30°C |

| Air Seal / Clean Air Pressure | 2 – 7 bar | |

| Tool Release Pressure | 5 – 7 bar | |

| Tool Release Air Volume | 184 cm³ |

Primary Applications

This versatile spindle is perfectly suited for:

- Job Shops & Multi-Task Facilities: One spindle handles diverse materials (using Y-mode for steel, Δ-mode for aluminum).

- Mold & Die Manufacturing: Roughing of hardened steels (Y-mode) and high-speed finishing of electrodes or cavities (Δ-mode).

- Precision Component Production: For automotive, aerospace, and general engineering sectors.

- Any machining center using Mitsubishi controls that requires a reliable, high-performance, and adaptable spindle solution.

Value Proposition

The A2001901 eliminates the need to choose between a torque-focused or speed-focused spindle. It offers two performance profiles in one reliable unit, maximizing your machine’s versatility and uptime. Its guaranteed compatibility with the Mitsubishi ecosystem reduces integration risk and ensures optimal performance.