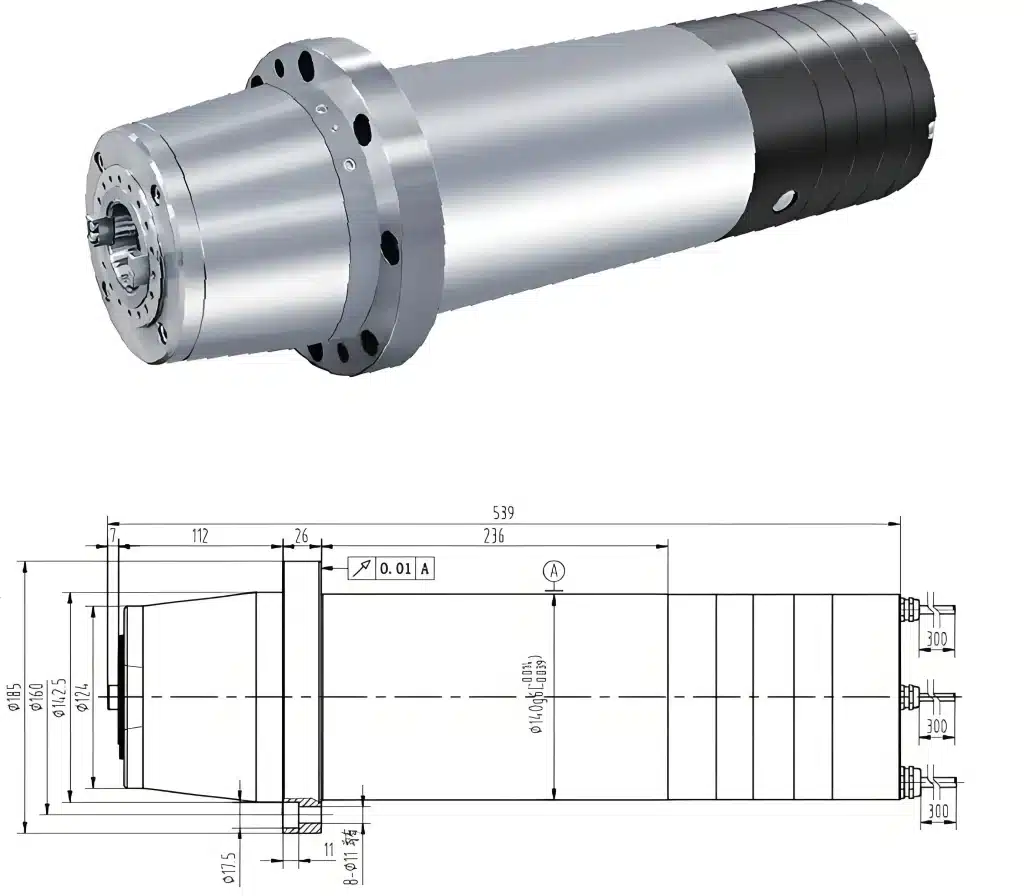

A2004561 High-Performance Milling Spindle

140mm Diameter | 30 N·m High Torque | Engineered for Heavy-Duty Machining & Precision Engraving

The A2004561 is a high-power, high-rigidity electric spindle designed for demanding applications in precision engraving, milling, and vertical machining centers. Built with a substantial 140mm outer diameter, it delivers an exceptional combination of 30 N·m high torque and 11 kW power, supported by ultra-high structural stiffness. Engineered for stability and accuracy, it is the ideal core component for machining tough materials and complex geometries where rigidity, power, and thermal control are critical.

Technical Overview

This spindle is engineered to bridge the gap between heavy-duty milling and high-precision engraving. Its robust construction focuses on minimizing deflection and thermal growth, ensuring consistent performance during long production cycles. The high torque output enables aggressive material removal, while the precision and stiffness guarantee fine detail and superior surface finishes.

Core Technical Advantages

- High Power & Exceptional Torque: 11 kW of power and 30 N·m of continuous torque provide formidable force for efficient milling of steels, stainless steels, and hard alloys.

- Ultra-High Rigidity for Accuracy: Outstanding axial stiffness (250 N/µm) and radial stiffness (750 N/µm) create an incredibly stable platform. This minimizes vibration and tool deflection, ensuring dimensional accuracy and excellent surface quality even during heavy cuts or fine engraving.

- Optimized Thermal Management: A high-capacity liquid cooling system (>10 L/min) effectively controls heat, reducing thermal elongation to maintain precision over extended operation periods—a key factor for long-duration machining tasks.

- Designed for Automation & Reliability: Equipped with a BBT40 tool holder, high drawbar force (6500 ± 500 N), and PNP/NO tool change signals for reliable integration into automated systems. The heavy-duty bearing configuration (71910×2 / 71913×4) ensures longevity.

- Precision Engineering: Achieves a high-precision taper runout of ≤2.0 µm (at 25mm) and a G0.4 balance grade, contributing to smooth operation and fine finish capability.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Spindle Designation | Electric Spindle |

| Model | A2004561 | |

| Spindle Outer Diameter | 140 mm | |

| Mounting Orientation | Horizontal | |

| Tool Holder | BBT40 | |

| Drive Method | Built-in Motor | |

| Warranty | 1 Year | |

| Performance | Maximum Speed | 18,000 rpm |

| Rated Power | 11 kW | |

| Rated Torque | 30 N·m | |

| Radial Stiffness | 750 N/µm | |

| Axial Stiffness | 250 N/µm | |

| Taper Runout | ≤ 2.0 µm (at 25mm); ≤ 8.0 µm (at 300mm) | |

| Face Runout | ≤ 2.0 µm | |

| Dynamic Balance Grade | G0.4 | |

| Drawbar Force | 6500 ± 500 N | |

| Mechanical Construction | Bearing Specification | 71910 × 2, 71913 × 4 |

| Lubrication | Grease | |

| Spindle Weight | 49 kg | |

| Packing Weight (Wooden Case) | 56 kg (Spindle: 49kg + Case: 7kg) | |

| System Interfaces | Encoder Signal | Sine Wave / 160-tooth |

| Tool Change Signal | PNP / NO (Normally Open) | |

| Cooling & Pneumatics | Cooling Method | Oil or Water Coolant Flow > 10 L/min, Cooling Power > 1 kW, Max. Inlet Temp 30°C |

| Air Seal Pressure | 2 – 7 bar | |

| Clean Air Pressure | 2 – 7 bar | |

| Tool Release Pressure | 5 – 7 bar | |

| Tool Release Air Volume | 335 cm³ |

Primary Applications

This versatile, high-rigidity spindle is perfectly suited for:

- Heavy-Duty Milling and roughing of steel and cast iron components.

- Precision Engraving and detailed 3D machining of molds and dies.

- High-Productivity Machining on vertical machining centers (VMCs).

- Manufacturing of structural parts in the aerospace, automotive, and energy sectors.

Value Proposition

The A2004561 is built to be the dependable powerhouse in your machine tool. It transforms capability by allowing for faster material removal with confidence, ensuring part accuracy through superior stiffness, and maintaining reliability in continuous operation. It is a robust solution designed to maximize productivity and output quality in challenging machining environments.

Power and Precision for Demanding Applications. Contact our technical team today to discuss how the A2004561 High-Performance Spindle can be integrated into your machining center to enhance its capabilities.