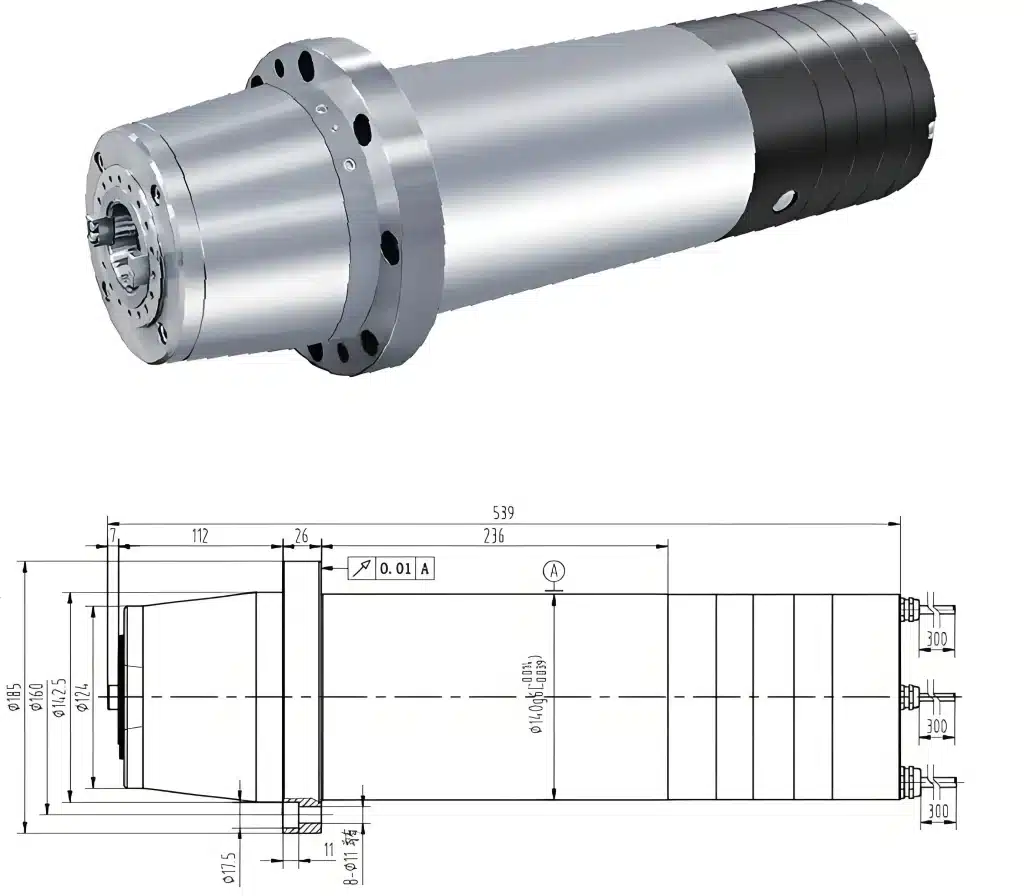

A2003071 High-Performance Dual-Mode Spindle for Mitsubishi Systems

140mm Diameter | Up to 28.55 N·m Torque | Y/Δ Configuration for Ultimate Machining Versatility

The A2003071 is a premium, high-rigidity electric spindle engineered as a powerhouse for vertical machining centers and precision engraving machines equipped with Mitsubishi CNC controls. Its core innovation is the Y/Δ dual-winding system, allowing a single spindle to operate as both a high-torque heavy-duty unit (28.55 N·m) and a high-power, higher-speed spindle. Combined with exceptional structural stiffness and thermal management, it delivers unmatched adaptability for a vast range of materials and machining strategies.

Technical Overview

Built with a robust 140mm outer diameter, the A2003071 is designed for stability and precision under extreme loads. It seamlessly integrates power with flexibility: choose immense torque for difficult materials or switch to a mode optimized for efficient high-speed machining. Pre-configured for the Mitsubishi ecosystem, it guarantees plug-and-play performance, reliability, and optimal servo control for demanding production environments.

Core Features & Advantages

- Dual-Mode Operational Excellence:

- Star (Y) Connection: Unleashes 28.55 N·m of massive torque at 6 kW, specifically engineered for aggressive roughing, deep cavity milling, and stable machining of hardened steels, titanium, and tough alloys.

- Delta (Δ) Connection: Delivers 8 kW of full power for operations up to 18,000 rpm, ideal for high-efficiency semi-finishing, milling of aluminum, and detailed 3D contouring.

- Certified Mitsubishi Compatibility: Equipped with a Mitsubishi serial encoder (GEL 2444M) and validated for M800/M80/E80/C80 series CNC and MDS-E/EH/EJ/EM/EMH-SP series drives. This ensures flawless communication, simplified setup, and robust, stable performance.

- Exceptional Structural Rigidity: Ultra-high radial stiffness (750 N/µm) and axial stiffness (250 N/µm) create an incredibly stable platform, minimizing vibration and deflection to ensure superior part accuracy and surface finish even during the most demanding cuts.

- Optimized Thermal Performance: A high-capacity liquid cooling system (>10 L/min) effectively manages heat, reducing thermal growth to maintain precision over long, uninterrupted machining cycles—critical for mold work and production runs.

- Robust Construction for Reliability: Features a heavy-duty bearing system (71910×2 / 71913×4), a BBT40 tool holder, and a very high drawbar force (6500 ± 500 N) for secure, vibration-free tool clamping under heavy loads.

Detailed Technical Specifications

| Parameter Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Spindle Designation | Electric Spindle |

| Model | A2003071 | |

| Tool Holder | BBT40 | |

| Lubrication | Grease | |

| Mounting Orientation | Vertical | |

| Drive Method | Built-in Motor | |

| CNC Compatibility | Mitsubishi M800/M80/E80/C80 | |

| Drive Compatibility | Mitsubishi MDS-E/EH/EJ/EM/EMH-SP Series | |

| Encoder Signal | GEL 2444M (Mitsubishi Serial) | |

| Tool Change Signal | PNP/NO | |

| Dynamic Balance Grade | G0.4 | |

| Warranty | 1 Year | |

| Spindle Weight | 49 kg | |

| Packing Weight (Wooden Case) | 7 kg | |

| Performance | Maximum Speed | 18,000 rpm |

| Axial Stiffness | 250 N/µm | |

| Radial Stiffness | 750 N/µm | |

| Taper Runout | ≤ 2.0 µm (at 25mm); ≤ 8.0 µm (at 300mm) | |

| Face Runout | ≤ 2.0 µm | |

| Rated Power (Star-Y / Delta-Δ) | 6 kW / 8 kW | |

| Rated Torque (Star-Y / Delta-Δ) | 28.55 N·m / 10.9 N·m | |

| Drawbar Force | 6500 ± 500 N | |

| Operating Conditions | Cooling Method | Oil/Water Coolant (Flow >10 L/min, Cooling Power >1 kW, Max. Inlet Temp. 30°C) |

| Air Seal Pressure | 2 – 7 bar | |

| Clean Air Pressure | 2 – 7 bar | |

| Tool Release Pressure | 5 – 7 bar | |

| Tool Release Air Volume | 335 cm³ |

Primary Applications

This versatile spindle is the ultimate solution for:

- Mold & Die Manufacturing: Heavy roughing of tool steels (Y-mode) and high-speed finishing of complex cores/cavities (Δ-mode).

- Aerospace & Automotive: Machining of structural components from titanium/steel (Y-mode) and aluminum alloys (Δ-mode).

- General Heavy-Duty Milling on vertical machining centers (VMCs) requiring both power and precision.

- Job Shops & High-Mix Production: Maximizes machine versatility by handling vastly different materials and operations with one spindle.

Value Proposition

The A2003071 eliminates the compromise between raw cutting force and high-speed capability. It provides two specialized spindles in one reliable, high-rigidity package, dramatically increasing your machining center’s flexibility and reducing downtime. Its guaranteed Mitsubishi integration delivers peace of mind and optimal performance.

Maximize Your Machining Center’s Potential. Contact our engineering team to discuss how the adaptable A2003071 Dual-Mode Spindle can be integrated into your Mitsubishi-controlled machine to tackle your most challenging projects.