A2005181 High-Performance Swivel Head Spindle for 5-Axis & Complex Machining

HSK-A63 | 150mm Diameter | 32.5 N·m Torque | 220V Dual Winding (Y/Δ) for Fanuc Systems

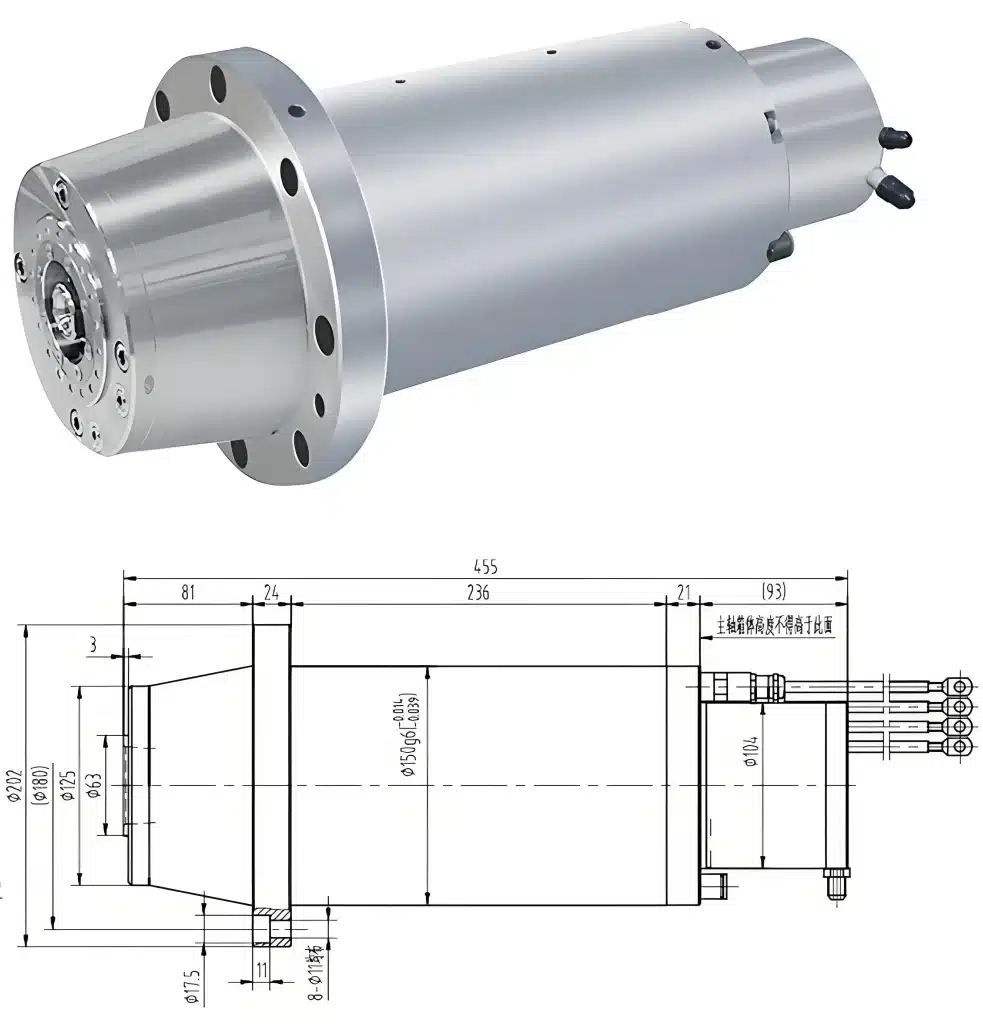

The A2005181 is a specialized high-torque electric spindle engineered for integration into swivel heads (pendulum heads) and angular milling heads on 5-axis machining centers and multi-tasking machines. Featuring a compact yet robust 150mm diameter housing and an HSK-A63 tool interface, it delivers exceptional flexibility through its 220V dual-winding motor, offering both high torque for demanding cuts and higher power for efficient machining. Designed with a flat mounting surface and keyway for secure orientation, it is the precision powerhouse for complex contouring, deep cavity work, and aerospace component manufacturing on compatible Fanuc-driven systems.

Technical Overview

This spindle is built for dynamic applications where the spindle itself rotates on one or more axes. Its design prioritizes a balanced profile, high rigidity, and reliable performance at various orientations. The dual-winding (Star/Delta) configuration allows the same spindle to deliver 32.5 N·m of focused torque for challenging materials or 11 kW of power for productive milling, making it an incredibly versatile core component for advanced 5-axis machining.

Core Performance Advantages

- Optimized for Swivel Head Integration: The 150mm cylindrical design with a integrated flange and flat/keyway ensures rigid and repeatable mounting within angular head units, critical for maintaining accuracy in multi-axis machining.

- Dual-Winding Operational Flexibility:

- Star (Y) Connection: Provides 32.5 N·m of high torque at 6 kW, ideal for stable machining of titanium, Inconel, hardened steels, and other difficult alloys in a swivel head application.

- Delta (Δ) Connection: Delivers 11 kW of power and 18.8 N·m torque, optimized for high-efficiency milling of aluminum, composites, and detailed finishing across complex surfaces.

- Exceptional Rigidity in a Compact Format: High radial stiffness (600 N/µm) ensures minimal deflection during side-cutting and off-center milling operations common in 5-axis work.

- Heavy-Duty Tool Clamping for Complex Orientations: The HSK-A63 interface combined with an extremely high drawbar force (18,000 ± 2,000 N) guarantees tool security even during heavy cuts in inverted or angled positions.

- Complete FANUC System Integration: Engineered for seamless integration with FANUC CNC controls and αi or βi series servo drives. The standard 160-tooth Sine Wave encoder and PNP tool change signals guarantee reliable communication, simplified setup, and optimal performance.

- Effective Thermal Management: A high-capacity liquid cooling system (>10 L/min) is essential to manage heat and maintain precision during long, uninterrupted machining cycles in complex parts.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Spindle Designation | Swivel Head Electric Spindle |

| Model | A2005181 | |

| Primary Application | 5-Axis Swivel / Angular Milling Head | |

| Tool Interface & Drive | Tool Holder | HSK-A63 (with Flange & Drive Flat) |

| Drive System | Built-in Motor, 220V Dual Winding (Y/Δ) | |

| Compatible Control | Fanuc CNC & Drive Systems | |

| Encoder Signal | Sine Wave / 160-tooth | |

| Performance & Power | Maximum Speed | 20,000 rpm |

| Rated Power (Y / Δ) | 6 kW (Y) / 11 kW (Δ) | |

| Rated Torque (Y / Δ) | 32.5 N·m (Y) / 18.8 N·m (Δ) | |

| Axial Stiffness | 200 N/μm | |

| Radial Stiffness | 600 N/μm | |

| Precision & Construction | Bearing Specification | 71912 × 4, 71909 × 2 |

| Lubrication | Grease | |

| Taper Runout | ≤ 2.0 μm (at 25mm); ≤ 8.0 μm (at 300mm) | |

| Face Runout | ≤ 2.0 μm | |

| Dynamic Balance Grade | G0.4 | |

| Clamping & Automation | Drawbar Force | 18,000 ± 2,000 N |

| Tool Change Signal | PNP / NO | |

| Tool Release Oil Pressure | 5 – 7 MPa | |

| Cooling & Auxiliary | Cooling Method | Oil/Water Coolant (>10 L/min, >1.5 kW) |

| Tool Coolant Max. Pressure | 7 bar | |

| Air Seal / Clean Air Pressure | 2 – 7 bar | |

| Quality Assurance | Warranty | 1 Year |

Primary Applications

This spindle is engineered for advanced multi-axis machining, including:

- 5-axis contouring of aerospace structural components (blisks, impellers, bulkheads).

- Deep cavity and undercut machining in complex mold and die manufacturing.

- Angular milling and drilling on multi-tasking machines and machining centers with swivel attachments.

- Production of prototypes and parts with complex geometries requiring simultaneous multi-axis movement.

Value Proposition

The A2005181 unlocks the full potential of your 5-axis or angular head capabilities. It provides the necessary power, rigidity, and configuration flexibility to machine complex parts efficiently and accurately in a single setup. By combining high torque for tough materials with high power for productivity, it is a strategic investment for shops specializing in advanced, value-added manufacturing.

Engineer Complex Parts with Confidence. Contact our technical team to discuss integrating the A2005181 Swivel Head Spindle into your Fanuc-based 5-axis system or angular head unit.