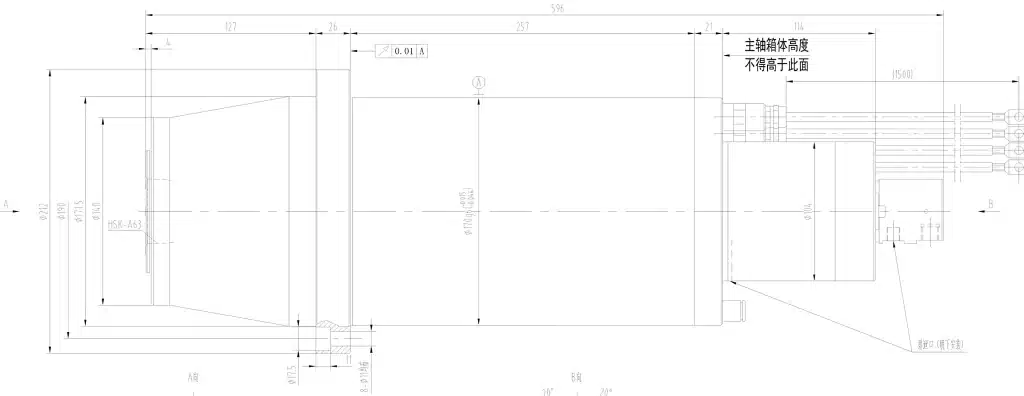

A2004451 Ultra-High-Power Machining Spindle

30 kW | 72 N·m | 170mm HSK-A63 | The Ultimate Heavy-Duty Solution for Gantry & Boring Mills

The A2004451 is a monumental electric spindle engineered to deliver uncompromising power and rigidity for the most demanding industrial machining applications. With a colossal 30 kW of power and 72 N·m of torque housed within a 170mm diameter body, it is purpose-built for heavy roughing, high-efficiency milling, and deep cavity work on large gantry machining centers, floor-type boring mills, and high-power vertical/horizontal machining centers. Featuring an HSK-A63 tool interface, a versatile design for both vertical and horizontal mounting, and an integrated 7 MPa through-spindle coolant system, it sets a new standard for productivity in machining high-strength alloys and large-scale components.

Technical Overview

This spindle represents the pinnacle of heavy-duty drive technology, designed to transform large machine tools into supremely productive assets. Its core philosophy integrates extreme cutting force with exceptional structural integrity and advanced thermal management. The 380V single-winding motor ensures broad compatibility with mainstream industrial drive systems, while its massive 900 N/µm radial stiffness provides the foundational stability required for precision under extreme loads.

Core Performance Advantages

- Unmatched Power & Torque: Delivers a transformative 30 kW of continuous power and 72 N·m of torque, enabling dramatically reduced cycle times for roughing and high-feed milling of hardened steels, titanium, Inconel, and heavy castings.

- Extreme Structural Rigidity: An exceptional radial stiffness of 900 N/µm and axial stiffness of 300 N/µm create an ultra-stable platform that virtually eliminates deflection and vibration, ensuring part accuracy and superior surface finish even during the most aggressive cuts.

- Advanced Integrated Cooling: A high-capacity spindle jacket cooling system (>10 L/min) works in concert with a high-pressure through-spindle coolant (7 MPa) to effectively manage heat at the source, enhancing tool life, enabling efficient deep-hole operations, and guaranteeing long-term thermal stability.

- Versatile & Robust Integration: The 380V single-winding design offers seamless compatibility with Siemens, Fanuc, and other third-party drives. Engineered for both vertical and horizontal installation, it provides maximum flexibility for machine builders and integrators.

- Heavy-Duty Reliability: A premium bearing configuration (71910×2 / 71914×4) and an extremely high drawbar force (18,000 ± 2,000 N) ensure secure tool clamping and deliver reliable, maintenance-free operation in continuous production environments.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model | A2004451 |

| Housing Diameter | 170 mm | |

| Mounting Orientation | Vertical or Horizontal | |

| Power & Performance | Rated Power | 30 kW |

| Rated Torque | 72 N·m | |

| Maximum Speed | 18,000 rpm | |

| Axial / Radial Stiffness | 300 N/µm / 900 N/µm | |

| Tool Interface & Drive | Tool Holder | HSK-A63 |

| Motor & Voltage | 380 V, Single Winding | |

| Encoder Signal | Sine Wave / 160-tooth | |

| Precision & Construction | Taper Runout | ≤ 2.0 µm @ 25mm |

| Face Runout | ≤ 2.0 µm | |

| Bearing System | 71910 × 2, 71914 × 4 (Grease) | |

| Dynamic Balance | G0.4 | |

| Clamping & Automation | Drawbar Force | 18,000 ± 2,000 N |

| Tool Change Signal | PNP / NO | |

| Tool Release Pressure | 5 – 7 MPa | |

| Cooling Systems | Spindle Body Cooling | Oil/Water Coolant (>10 L/min, >2 kW) |

| Center Through Coolant (CTC) | Max Pressure: 7 MPa | |

| Air Seal / Purge | 2 – 7 bar | |

| Physical Data & Warranty | Net Weight | 109 kg |

| Warranty | 1 Year |

Primary Applications

This spindle is the definitive solution for large-scale, high-power machining, including:

- Heavy roughing and finishing of large forging dies, mold bases, and industrial molds.

- Machining of critical structural components for aerospace (frames, landing gear parts), energy (turbine housings, valves), and heavy machinery.

- High-productivity milling on large gantry machining centers and floor-type boring mills.

- Deep cavity machining and high-efficiency face milling of massive workpieces.

Value Proposition

The A2004451 is engineered to be a strategic productivity multiplier. It empowers manufacturers to tackle their most challenging projects with confidence, significantly reducing machining times while upholding the highest standards of accuracy and surface quality. Its robust design and versatile integration options make it a cornerstone investment for achieving a competitive edge in heavy industrial manufacturing.

Engineer Unrivaled Productivity. Contact our engineering team to discuss integrating the A2004451 Ultra-High-Power Spindle into your heavy-duty machining platform.