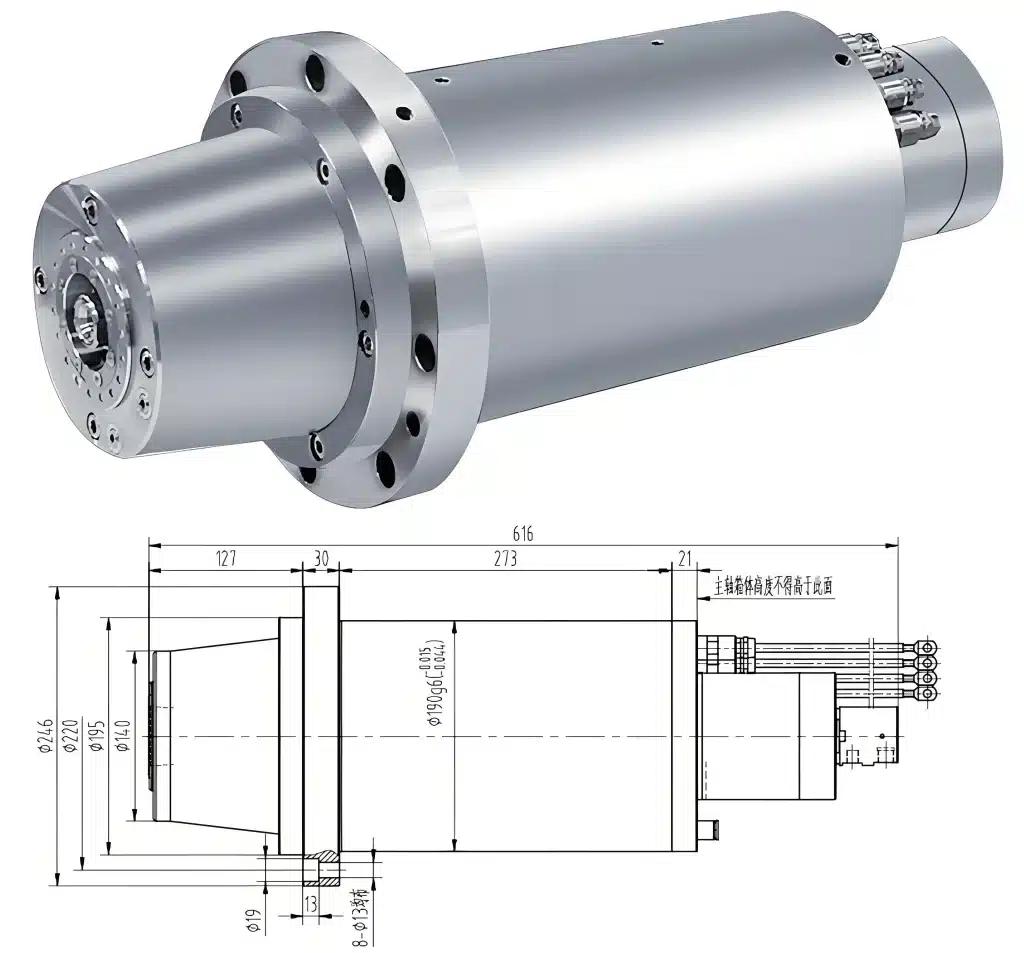

A2004521 High-Torque Dual-Winding Spindle

103.8 N·m Torque | 45 kW Power | 190mm HSK-A63 | Dual-Mode Powerhouse for Heavy-Duty Machining

The A2004521 is an exceptional electric spindle engineered to deliver unparalleled versatility and raw cutting force for the most demanding industrial applications. Featuring a robust 190mm diameter and an HSK-A63 tool interface, its core innovation lies in the 400V dual-winding (Y/Δ) motor, offering two distinct operational profiles: an ultra-high torque mode (103.8 N·m) for extreme heavy-duty cutting, and a high-power mode (45 kW) for maximum material removal rates. Designed for vertical installation on large machining centers and gantry mills, and equipped with a 7 MPa through-spindle coolant system, it is the ultimate solution for machining high-strength alloys, large molds, and heavy structural components with supreme efficiency.

Technical Overview

This spindle is built to provide machine shops with strategic flexibility without compromising performance. Its dual-winding architecture allows a single spindle unit to excel in vastly different machining regimes. Whether the priority is conquering the toughest materials with immense torque or maximizing productivity with high power and speed, the A2004521 adapts to the task. Combined with extreme rigidity and advanced cooling, it is designed to be a transformative asset for high-mix, heavy-duty production.

Core Performance Advantages

- Dual-Winding Operational Mastery: Choose the optimal performance profile for each job.

- Star (Y) Connection: Unleashes a colossal 103.8 N·m of torque at 32 kW, specifically engineered for stable, heavy roughing of hardened steels, titanium, Inconel, and deep cavity milling where cutting force is critical.

- Delta (Δ) Connection: Delivers 45 kW of maximum power and 72.9 N·m torque, optimized for high-efficiency roughing and semi-finishing, high-feed milling, and machining of large workpieces where material removal rate is paramount.

- Extreme Structural Rigidity: An exceptional radial stiffness of 900 N/µm provides a rock-solid foundation that minimizes vibration and deflection, ensuring dimensional accuracy and superior surface finish even under the most aggressive loads in either operational mode.

- Advanced Thermal & Chip Management: A high-flow cooling system (>10 L/min) manages spindle heat, while the integrated high-pressure through-spindle coolant (7 MPa) directly targets the cutting zone, dramatically improving tool life and enabling efficient deep-hole drilling and milling operations.

- Heavy-Duty Reliability & Clamping: The premium bearing configuration (71910×2 / 71914×4) and an extremely high drawbar force (18,000 ± 2,000 N) ensure secure tool retention and deliver dependable, long-term performance in the most punishing continuous production environments.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model | A2004521 |

| Housing Diameter | 190 mm | |

| Mounting Orientation | Vertical | |

| Power & Performance | Motor Configuration | 400V, Dual Winding (Y/Δ) |

| Rated Power (Y / Δ) | 32 kW (Y) / 45 kW (Δ) | |

| Rated Torque (Y / Δ) | 103.8 N·m (Y) / 72.9 N·m (Δ) | |

| Maximum Speed | 18,000 rpm | |

| Axial / Radial Stiffness | 300 N/µm / 900 N/µm | |

| Tool Interface & Drive | Tool Holder | HSK-A63 |

| Encoder Signal | Sine Wave / 160-tooth | |

| Precision & Construction | Taper Runout | ≤ 2.0 µm @ 25mm |

| Face Runout | ≤ 2.0 µm | |

| Bearing System | 71910 × 2, 71914 × 4 (Grease) | |

| Dynamic Balance | G0.4 | |

| Clamping & Automation | Drawbar Force | 18,000 ± 2,000 N |

| Tool Change Signal | PNP / NO | |

| Tool Release Pressure | 5 – 7 MPa | |

| Cooling Systems | Spindle Body Cooling | Oil/Water Coolant (>10 L/min, >2 kW) |

| Center Through Coolant (CTC) | Max Pressure: 7 MPa | |

| Air Seal / Purge | 2 – 7 bar | |

| Physical Data & Warranty | Net Weight | 109 kg |

| Warranty | 1 Year |

Primary Applications

This versatile, high-power spindle is engineered for:

- Heavy-duty roughing and machining of high-strength materials on large vertical machining centers, gantry mills, and floor-type boring mills.

- Manufacturing of large, complex molds and dies for the automotive and heavy industry sectors.

- Machining of critical structural components in aerospace (landing gear, frames) and energy (large valves, turbine components).

- Job shops and production facilities that require one spindle to handle a wide range of materials and operations, from high-torque cutting to high-power milling.

Value Proposition

The A2004521 redefines versatility in heavy machining. It consolidates the capabilities of two specialized spindles into one reliable unit, offering unmatched flexibility to optimize machining strategies for different materials and features. This adaptability maximizes your machine tool’s utilization, reduces changeover needs, and provides a formidable competitive edge in tackling diverse, high-value manufacturing projects.

Configure Your Ultimate Machining Strategy. Contact our engineering team to discuss how the adaptable, high-power A2004521 Dual-Winding Spindle can be integrated into your large machining center to unlock new levels of productivity and capability.