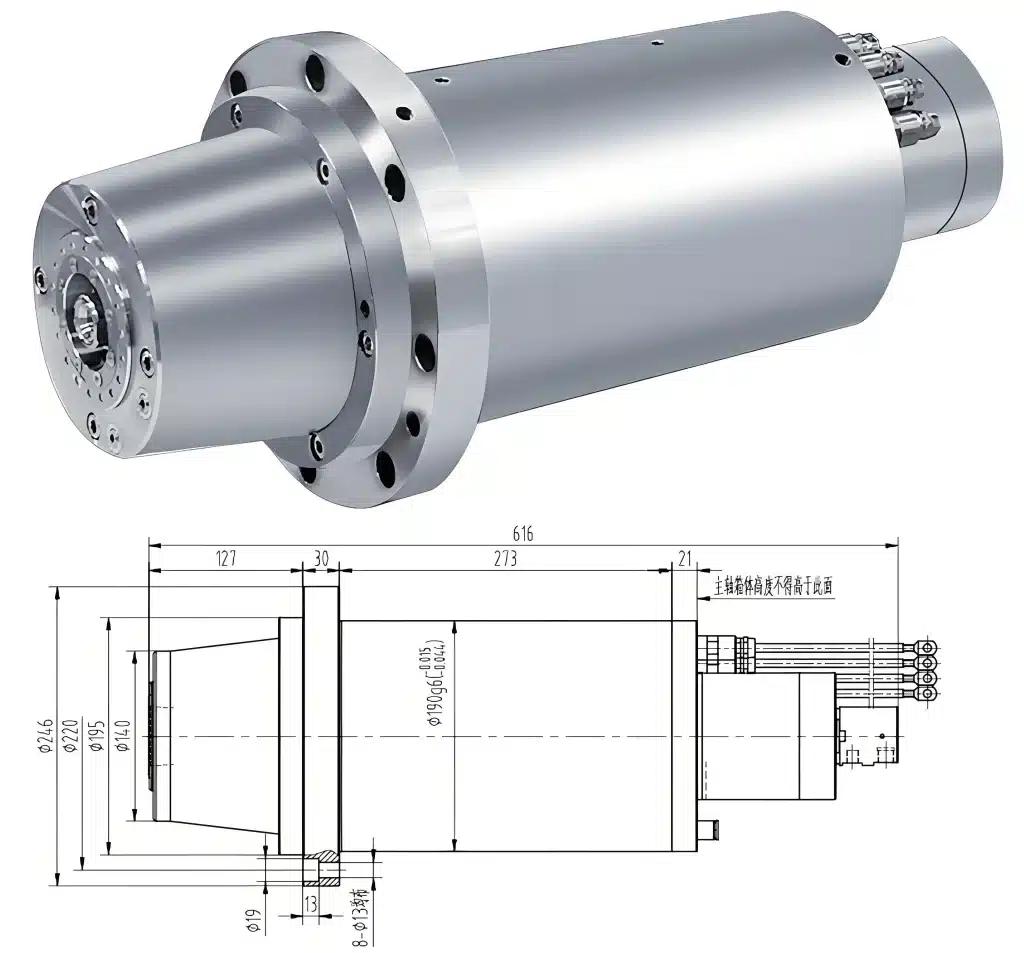

A2005311 Dual-Winding High-Torque Spindle for Mitsubishi Systems

BBT40 | 90.38 N·m Torque | Certified for Seamless Mitsubishi Integration

The A2005311 is a precision-engineered, dual-winding electric spindle designed to deliver exceptional torque density and operational flexibility for demanding milling applications. Built with a robust 190mm diameter and a BBT40 tool interface, it features a Mitsubishi-optimized design that offers two distinct performance profiles: an ultra-high torque mode (90.38 N·m) for challenging materials and a high-power mode (18.5 kW) for efficient machining. Pre-configured with a Mitsubishi serial encoder and drive compatibility, and equipped with a 7 MPa through-spindle coolant system, it guarantees plug-and-play performance, reliability, and precision for vertical machining centers within the Mitsubishi ecosystem.

Technical Overview

This spindle is engineered to provide maximum versatility without compromising on integration ease. Its dual-winding (Y/Δ) motor allows users to strategically select the optimal balance of torque and power for specific materials and operations. Fully certified for the Mitsubishi control and drive platform, it eliminates compatibility concerns and ensures optimal servo performance, making it an ideal, low-risk upgrade or replacement for high-productivity workshops.

Core Performance Advantages

- Strategic Dual-Winding Flexibility: Enables optimized machining strategies by selecting the appropriate operating mode.

- Star (Y) Connection: Delivers an impressive 90.38 N·m of high torque at 15 kW, specifically engineered for stable machining of difficult-to-cut materials like titanium, Inconel, and hardened steels, where cutting force is critical over raw speed.

- Delta (Δ) Connection: Provides 18.5 kW of power and 35.23 N·m torque, optimized for high-efficiency milling, semi-finishing, and operations on materials like aluminum and cast iron where higher speeds are beneficial.

- Certified Mitsubishi Compatibility & Reliability: Equipped with a Mitsubishi serial encoder (GEL 2444M) and validated for M800/M80/E80/C80 series CNC and MDS-D/E/EM/EJ/EMH-SP series drives. This ensures flawless communication, simplified setup, and dependable, high-performance operation.

- Exceptional Rigidity for Precision: High radial stiffness (900 N/µm) and axial stiffness (300 N/µm) provide a stable foundation that minimizes vibration and deflection, ensuring part accuracy and superior surface finish under load.

- Integrated Coolant for Process Efficiency: The 7 MPa through-spindle coolant capability is crucial for effective chip evacuation in deep-pocket milling and drilling, extending tool life and enabling uninterrupted machining cycles.

- Robust Construction: Features a heavy-duty bearing system (71910×2 / 71914×4) and a substantial drawbar force (8000 ± 1000 N) to ensure secure tool clamping and long-term reliability in continuous production.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model | A2005311 |

| Housing Diameter | 190 mm | |

| Mounting Orientation | Vertical | |

| Power & Performance | Motor Configuration | Dual Winding (Y/Δ) |

| Rated Power (Y / Δ) | 15 kW (Y) / 18.5 kW (Δ) | |

| Rated Torque (Y / Δ) | 90.38 N·m (Y) / 35.23 N·m (Δ) | |

| Maximum Speed | 18,000 rpm | |

| Axial / Radial Stiffness | 300 N/µm / 900 N/µm | |

| Tool Interface & Drive | Tool Holder | BBT40 |

| Compatible Control System | Mitsubishi M800/M80/E80/C80 Series | |

| Encoder | Mitsubishi Serial (GEL 2444M) | |

| Precision & Construction | Taper Runout | ≤ 2.0 µm @ 25mm |

| Face Runout | ≤ 2.0 µm | |

| Bearing System | 71910 × 2, 71914 × 4 (Grease) | |

| Dynamic Balance | G0.4 | |

| Clamping & Automation | Drawbar Force | 8000 ± 1000 N |

| Tool Change Signal | PNP / NO | |

| Cooling Systems | Spindle Body Cooling | Oil/Water Coolant (>10 L/min, >2 kW) |

| Center Through Coolant (CTC) | Max Pressure: 7 MPa | |

| Physical Data & Warranty | Net Weight | 109 kg |

| Warranty | 1 Year |

Primary Applications

This versatile spindle is ideally suited for:

- Heavy-duty machining of high-strength alloys (using Y-mode) on vertical machining centers.

- Mold and die manufacturing, combining roughing of hard steels with efficient semi-finishing.

- Aerospace and automotive component production requiring a mix of high-torque and high-power operations.

- Job shops using Mitsubishi controls that need a reliable, high-performance spindle for a diverse range of materials.

Value Proposition

The A2005311 offers Mitsubishi users a smart, flexible spindle solution that adapts to the job at hand. It combines the assurance of certified compatibility with the performance benefits of a dual-winding design, maximizing your machine’s capability and uptime. It is the strategic choice for enhancing productivity and tackling a wider range of workpieces with confidence.

Optimize Your Mitsubishi Machining Center. Contact our engineering team to configure and integrate the A2005311 Dual-Winding Spindle for your specific application requirements.