A2004711 Ultra-High-Torque Spindle for Mitsubishi Systems

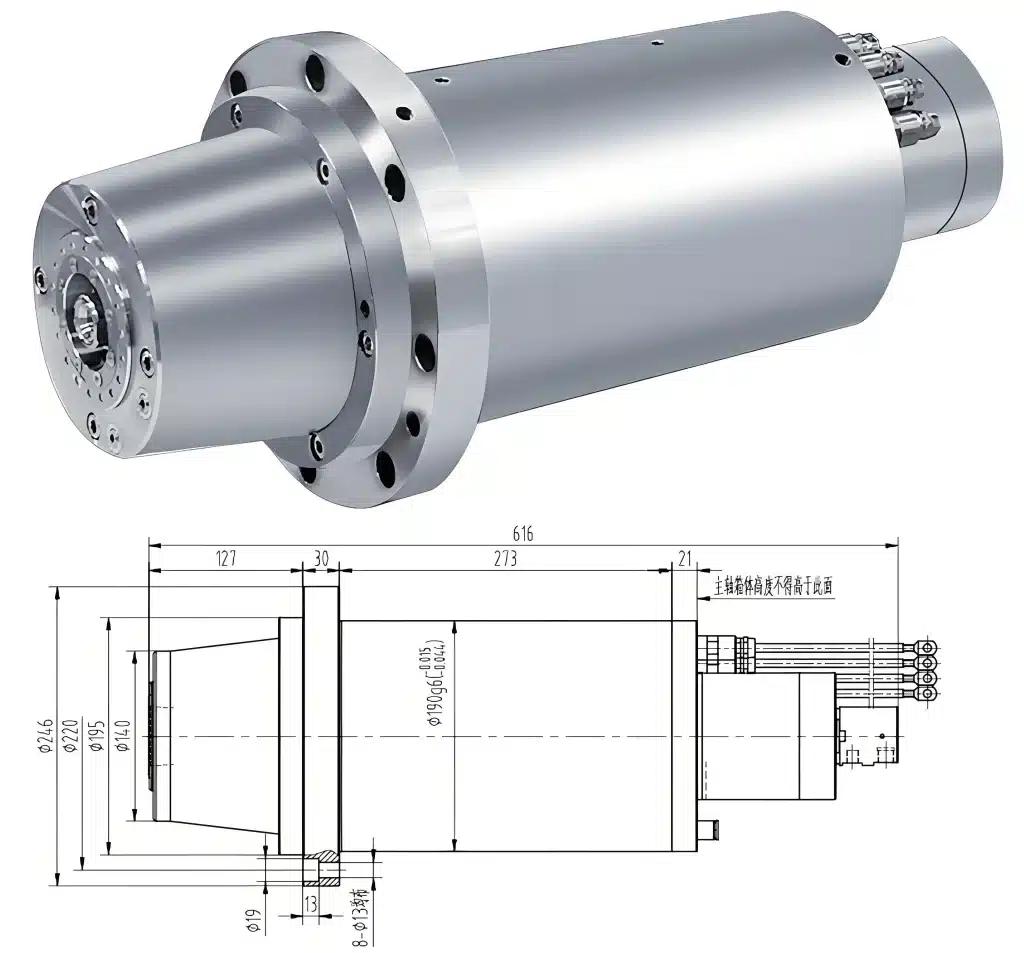

BBT50 | 143 N·m Max Torque | 190mm | Redefining Heavy-Duty Cutting with Extreme Rigidity

The A2004711 is engineered for a singular purpose: to deliver unmatched torque and structural integrity for the most demanding heavy-duty milling applications on large vertical machining centers and gantry mills within the Mitsubishi ecosystem. While sharing a similar 190mm outer diameter with other models, its design philosophy diverges significantly, prioritizing extreme torque (143 N·m) and maximum rigidity (1000 N/µm radial stiffness) over raw high-speed power. Equipped with a robust BBT50 tool interface and fully certified for Mitsubishi CNC systems, this spindle is the definitive solution for stable, powerful machining of high-strength materials where cutting force and process stability are non-negotiable.

Technical Overview & Key Differentiator

The A2004711 distinguishes itself within the 190mm spindle class by being a dedicated ultra-high-torque, high-rigidity specialist. Unlike models optimized for high power or dual-mode versatility, this spindle’s core is built around a massive bearing configuration and a motor winding designed to generate immense, stable torque at lower speeds. This makes it exceptionally capable for deep cavity milling, heavy face milling, and roughing of tough alloys where traditional spindles might stall or chatter. Its certified plug-and-play compatibility with Mitsubishi controls ensures this brute force is delivered with precision and reliability.

Key Distinction from Other 190mm Spindles:

- Design Core: Extreme Torque & Maximum Rigidity vs. High Power or Balanced Speed/Torque.

- Primary Metric: 143 N·m (Y) Rated Torque – the highest in its class for stable low-speed power.

- Structural Benchmark: 1000 N/µm Radial Stiffness – providing an unparalleled foundation against deflection.

- Tool Interface: BBT50 – a larger, more robust taper for heavy-load power transmission compared to BBT40 or HSK-A63.

- Best For: Aggressive heavy roughing, deep cuts in hardened materials where removing cubic inches per minute with stability is the goal.

Core Performance Advantages

- Class-Leading Torque for Heavy Cuts: Generates a massive 143 N·m of torque in Star (Y) connection, providing the relentless force needed for efficient material removal in challenging alloys like hardened steel, titanium, and heavy castings.

- Unrivaled Structural Stability: The highest-in-class radial stiffness of 1000 N/µm creates an exceptionally rigid platform that virtually eliminates vibration and tool deflection, ensuring dimensional accuracy and protecting tool integrity during the most aggressive operations.

- Optimized Heavy-Duty Interface: The BBT50 tool holder is specifically designed for higher torque transmission and more secure clamping under extreme loads compared to smaller tapers, making it ideal for large-diameter milling cutters.

- Guaranteed Mitsubishi Integration: Pre-configured with a Mitsubishi serial encoder and validated for the complete Mitsubishi drive series, ensuring seamless setup, optimal servo performance, and dependable operation.

- Engineered for Reliability: An oversized bearing set (71918×4) and a very high drawbar force (15,000-20,000 N) are specified to handle the stresses of continuous heavy-duty machining, ensuring longevity and minimal downtime.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model | A2004711 |

| Housing Diameter | 190 mm | |

| Mounting Orientation | Vertical | |

| Power & Performance | Motor Configuration | Dual Winding (Y/Δ) |

| Rated Power (Y / Δ) | 15 kW (Y) / 18.5 kW (Δ) | |

| Rated Torque (Y / Δ) | 143 N·m (Y) / 71 N·m (Δ) | |

| Maximum Speed | 12,000 rpm | |

| Axial / Radial Stiffness | 500 N/µm / 1000 N/µm | |

| Tool Interface & Drive | Tool Holder | BBT50 |

| Compatible Control System | Mitsubishi M800/M80/E80/C80 Series | |

| Encoder | Mitsubishi Serial (GEL 2444M) | |

| Precision & Construction | Bearing System | 71918 × 4, N1012 × 1 (Grease) |

| Taper Runout | ≤ 2.0 µm @ 25mm | |

| Clamping & Automation | Drawbar Force | 15,000 – 20,000 N |

| Tool Change Signal | PNP / NO | |

| Cooling Systems | Spindle Body Cooling | Oil/Water Coolant (>10 L/min, >2 kW) |

| Center Through Coolant | Max Pressure: 7 MPa | |

| Physical Data & Warranty | Net Weight | 129 kg |

| Warranty | 1 Year |

Primary Applications

This spindle is the ultimate choice for specific, high-demand scenarios:

- Heavy roughing and profiling of large forging dies, mold bases, and industrial tooling.

- Deep slotting and cavity milling in high-strength steels and exotics where tool stability is critical.

- Machining of large, heavy components in the energy, mining, and heavy machinery sectors.

- Any application on a Mitsubishi-controlled machine where the primary challenge is overcoming material resistance with immense, stable cutting force.

Value Proposition

The A2004711 is not a general-purpose spindle; it is a specialized tool for conquering the toughest machining challenges. It offers Mitsubishi users a uniquely capable solution focused on maximum rigidity and torque, delivering superior results in heavy roughing applications where other spindles may be pushed to their limits. It translates directly into faster material removal, improved surface quality in tough materials, and greater confidence in pushing your machine’s capabilities.

Tackle Your Most Demanding Cuts with Confidence. Contact our engineering team to discuss integrating the A2004711 Ultra-High-Torque Spindle into your Mitsubishi machining center for unparalleled heavy-duty performance.