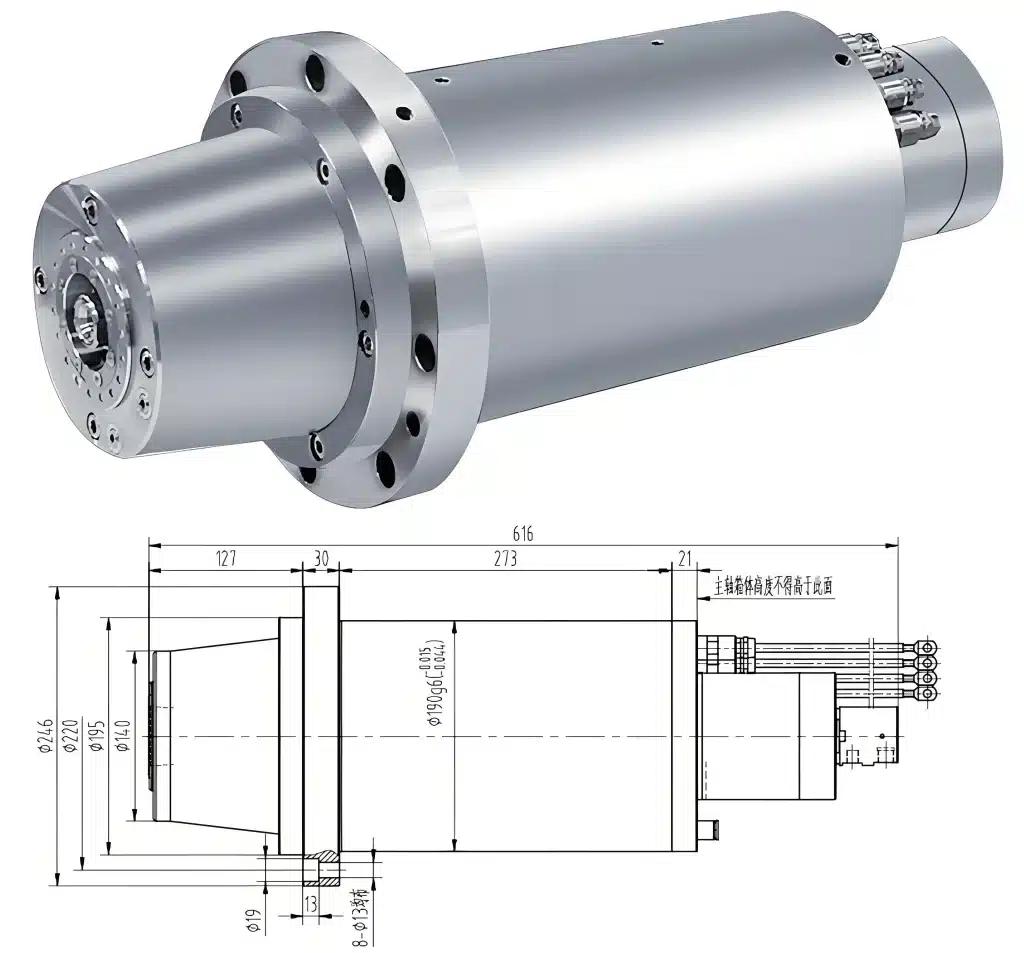

A2001760 Heavy-Duty Grinding Spindle

190mm | 90 N·m Torque | Engineered for High-Precision, High-Rigidity Grinding Applications

The A2001760 is a professional-grade electric spindle designed specifically for demanding grinding machines, such as cylindrical grinders, roll grinders, and large surface grinders. Built with a robust 190mm housing, it delivers exceptional torque (up to 90 N·m) and rigidity (1000 N/µm radial stiffness) necessary for stable, high-precision material removal on hardened steels, alloys, and large workpieces. Featuring ultra-precision bearings and optimized for horizontal installation, this spindle is the core component for achieving superior surface finishes, tight tolerances, and reliable performance in industrial grinding operations.

Technical Overview

This spindle is engineered from the ground up for the unique challenges of grinding, prioritizing process stability, thermal control, and precision over high rotational speed. Its high torque output and extreme radial stiffness minimize vibration and deflection during the grinding process, which is critical for achieving fine surface finishes and maintaining geometric accuracy on large or heavy components.

Core Performance Advantages

- High Torque & Power for Efficient Stock Removal: Delivers 90 N·m of torque in S6 duty cycle, enabling powerful and efficient grinding even on tough materials, reducing cycle times for roughing and finishing operations.

- Exceptional Rigidity for Grinding Stability: An outstanding radial stiffness of 1000 N/µm provides a rock-solid foundation that is essential for minimizing chatter and vibration, ensuring consistent part geometry and superior surface quality.

- Ultra-Precision Bearing System: Utilizes high-precision, P4-grade angular contact ball bearings (90BNR10 & 60BNR10 series) with grease lubrication, specifically selected for grinding applications to ensure smooth, quiet operation, long service life, and minimal runout.

- Optimized for Grinding Processes: The 3600 rpm maximum speed is tailored for optimal grinding wheel performance across a wide range of diameters and materials, balancing cutting speed with surface finish requirements.

- Robust Thermal Management: A dedicated liquid cooling system (>10 L/min) effectively manages heat generated during continuous grinding cycles, maintaining spindle accuracy and protecting critical components.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Spindle Type | Grinding Machine Electric Spindle |

| Model | A2001760 | |

| Housing Diameter | 190 mm | |

| Mounting Orientation | Horizontal | |

| Power & Performance | Rated Power (S1 / S6) | 11.5 kW / 17.0 kW |

| Rated Torque (S1 / S6) | 60 N·m / 90 N·m | |

| Maximum Speed | 3,600 rpm | |

| Axial / Radial Stiffness | 240 N/µm / 1000 N/µm | |

| Precision & Construction | Bearing Specification | 90BNR10STYNSUELP4Y, 60BNR10STYNSULP4Y (Grease) |

| Taper Runout | ≤ 2.0 µm | |

| Dynamic Balance Grade | G0.4 | |

| Cooling & Operation | Cooling Method | Oil / Water Coolant (>10 L/min, >1.5 kW) |

| Physical Data & Warranty | Net Weight | 90 kg |

| Warranty | 1 Year |

Primary Applications

This spindle is engineered for high-precision grinding tasks, including:

- External cylindrical grinding of shafts, rolls, and large precision components.

- Roll grinding for the paper, steel, and printing industries.

- Surface grinding of large plates and machine tool ways.

- Grinding of hardened materials and high-precision bearing races.

Value Proposition

The A2001760 Grinding Spindle translates precision engineering into tangible production benefits: improved part quality, reduced scrap rates, and consistent, reliable performance in demanding grinding environments. Its specialized design ensures it is not just a general-purpose spindle, but a dedicated solution for manufacturers who require the highest levels of accuracy and stability in their grinding operations.

Achieve Ultimate Grinding Precision and Power. Contact our team to discuss integrating the A2001760 Heavy-Duty Grinding Spindle into your grinding machine solution.