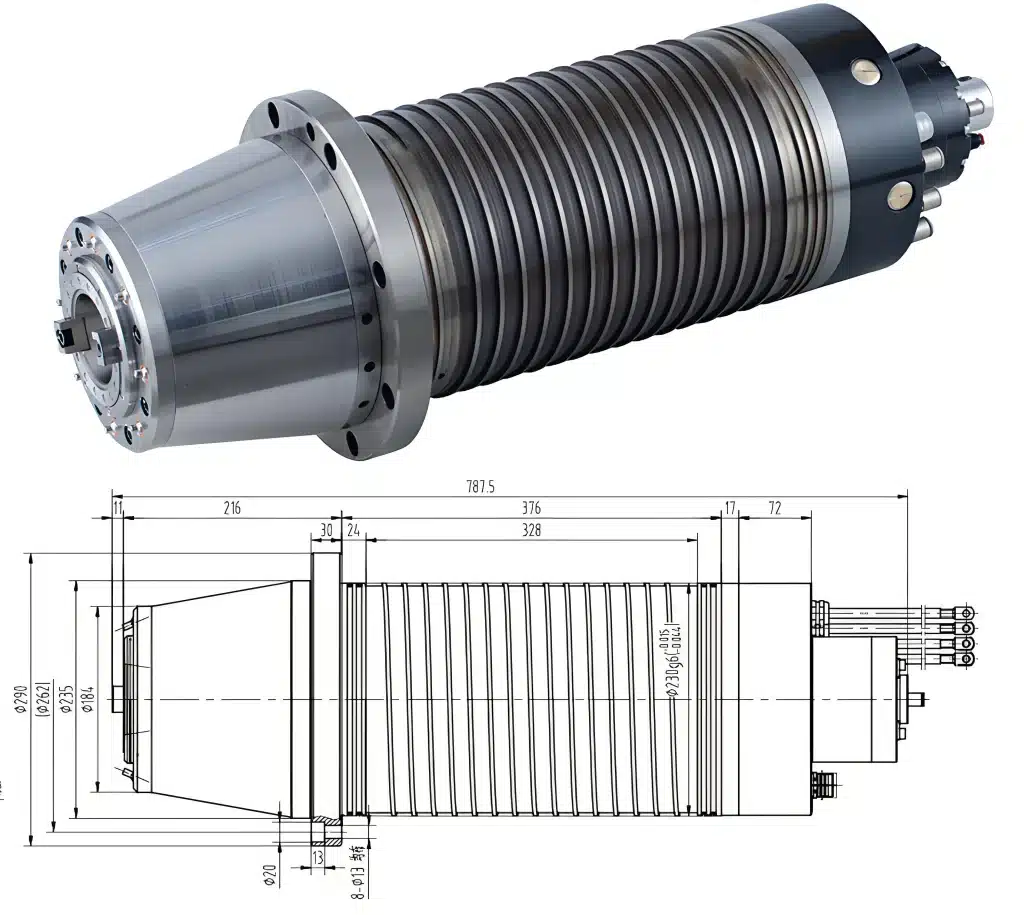

A2004861 High-Torque Dual-Winding Spindle for Fanuc Systems

HSK-A100 | 210 N·m Torque | 230mm | 220V Dual Winding | Optimized for Heavy-Duty Horizontal Machining

The A2004861 is a powerful, dual-winding electric spindle engineered for demanding heavy-duty milling and boring applications on large horizontal machining centers (HMCs) and floor-type boring mills. Built with a substantial 230mm housing and a robust HSK-A100 tool interface, it delivers exceptional 210 N·m of torque in Star (Y) connection from a 220V dual-winding motor fully compatible with Fanuc drive systems. Designed for horizontal installation and equipped with integrated high-pressure through-spindle coolant (7 MPa), this spindle combines immense cutting force, superior rigidity, and process cooling to maximize productivity in machining high-strength alloys and large components.

Technical Overview

This spindle is designed as a high-torque specialist for horizontal applications, where stability and powerful cutting force are paramount. The 220V dual-winding (Y/Δ) configuration offers strategic flexibility, allowing the same spindle to operate as an ultra-high-torque unit for tough materials or a higher-power unit for efficient milling. Its compatibility with Fanuc controls and substantial cooling capacity make it a reliable, high-performance core component for continuous heavy-duty production.

Core Performance Advantages

- Exceptional Dual-Winding Torque & Power: Provides unmatched operational versatility.

- Star (Y) Connection: Generates a massive 210 N·m of torque at 22 kW, specifically engineered for stable, heavy roughing, deep slotting, and machining of hardened steels, titanium, and heavy castings.

- Delta (Δ) Connection: Delivers 26 kW of power and 82.7 N·m torque, optimized for high-efficiency semi-finishing and milling operations where higher material removal rates are beneficial.

- Fanuc Drive System Compatibility: The 220V dual-winding motor is designed for seamless integration with Fanuc CNC and spindle drive systems, ensuring reliable performance, precise control, and easy setup.

- Extreme Structural Rigidity for Horizontal Machining: Outstanding radial stiffness (1000 N/µm) and axial stiffness (500 N/µm) provide a rock-solid foundation that minimizes deflection during heavy cuts, crucial for maintaining accuracy in horizontal milling and boring operations.

- Ultra-Secure HSK-A100 Interface: The large HSK-A100 tool holder combined with an immense drawbar force of 45,000 N ensures absolute tool security and optimal power transmission for large-diameter cutters under extreme loads.

- Advanced Integrated Cooling: A high-capacity cooling system (>16 L/min) manages spindle temperature, while the 7 MPa through-spindle coolant directly targets the cutting zone, significantly improving tool life and chip evacuation in deep-hole operations.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model | A2004861 |

| Housing Diameter | 230 mm | |

| Mounting Orientation | Horizontal | |

| Power & Performance | Motor Configuration | 220V, Dual Winding (Y/Δ) |

| Rated Power (Y / Δ) | 22 kW (Y) / 26 kW (Δ) | |

| Rated Torque (Y / Δ) | 210 N·m (Y) / 82.7 N·m (Δ) | |

| Maximum Speed | 12,000 rpm | |

| Axial / Radial Stiffness | 500 N/µm / 1000 N/µm | |

| Tool Interface & Drive | Tool Holder | HSK-A100 |

| Compatible System | Fanuc CNC & Drive Systems | |

| Encoder Signal | Sine Wave / 200-tooth | |

| Precision & Construction | Taper Runout | ≤ 2.0 µm @ 25mm |

| Bearing System | 71918 × 4, N1012 × 1 (Grease) | |

| Dynamic Balance | G0.4 | |

| Clamping & Automation | Drawbar Force | 45,000 ± 2,000 N |

| Tool Change Signal | PNP / NO | |

| Cooling Systems | Spindle Body Cooling | Oil/Water Coolant (>16 L/min, >3 kW) |

| Center Through Coolant (CTC) | Max Pressure: 7 MPa | |

| Physical Data & Warranty | Net Weight | 167 kg |

| Warranty | 1 Year |

Primary Applications

This spindle is engineered for the most demanding horizontal machining tasks:

- Heavy-duty horizontal milling and boring of large steel fabrications, weldments, and castings.

- Machining of large gearboxes, housings, and structural components in the energy, mining, and heavy equipment industries.

- Deep cavity and face milling on large horizontal machining centers.

- Roughing and semi-finishing of large molds and dies in a horizontal configuration.

Value Proposition

The A2004861 delivers Fanuc users a dedicated high-torque solution for horizontal machining challenges. Its dual-winding design provides the flexibility to optimize for either maximum cutting force or higher productivity, while its extreme rigidity and superior tool clamping ensure reliability and precision. This spindle is designed to transform your horizontal machining center into a more versatile and powerful asset for large-part manufacturing.

Power Your Heavy-Duty Horizontal Machining. Contact our engineering team to discuss integrating the A2004861 High-Torque Spindle into your Fanuc-controlled horizontal machining center or boring mill.