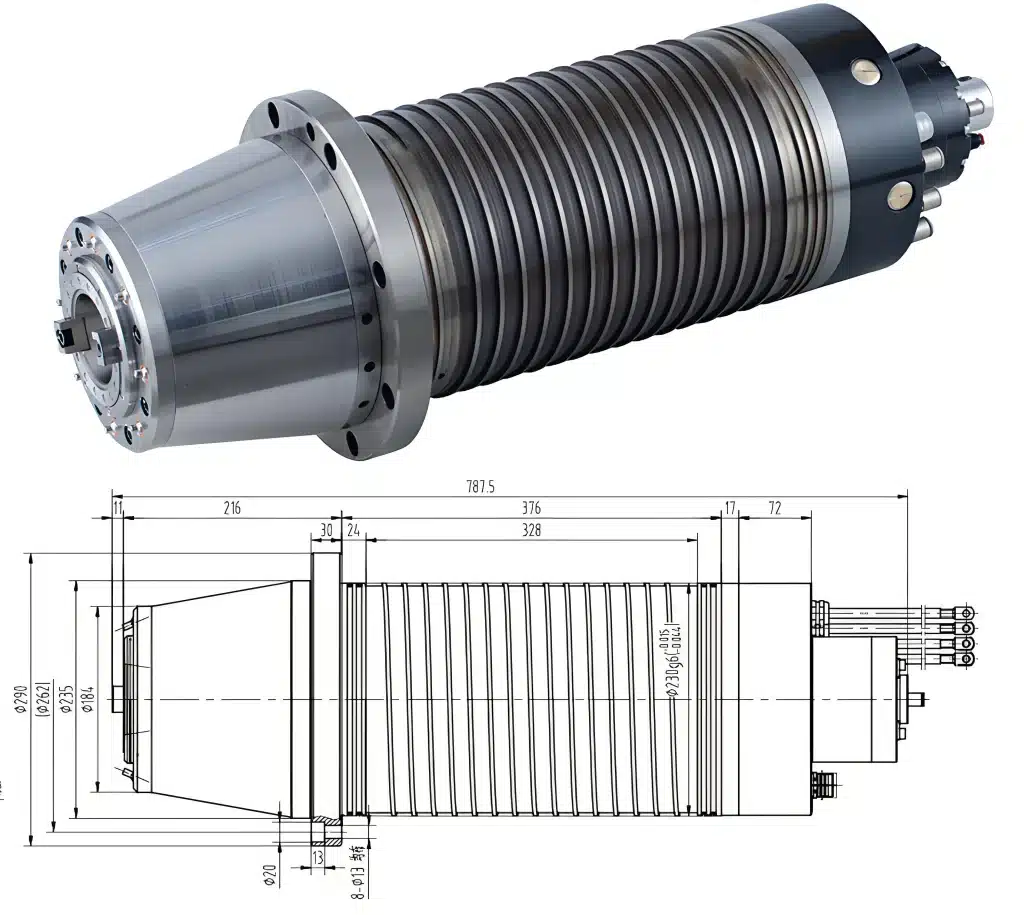

A2002051 High-Torque Dual-Winding Spindle for Mitsubishi Systems

BBT50 | 210 N·m Torque | 230mm | Certified for Seamless Mitsubishi Integration

The A2002051 is a high-performance, dual-winding electric spindle designed for robust vertical or horizontal machining centers operating within the Mitsubishi CNC ecosystem. Built with a 230mm housing and a BBT50 tool interface, it delivers exceptional torque and power flexibility through its dual-winding (Y/Δ) motor—offering either 210 N·m of high torque for heavy cutting or 26 kW of power for efficient milling. Pre-configured for Mitsubishi controls and drives, and engineered with high rigidity (1000 N/µm radial stiffness), this spindle ensures reliable, precision performance for demanding industrial applications.

Technical Overview

This spindle is engineered to provide strategic machining flexibility, allowing operators to choose between high-torque and high-power modes based on material and operation requirements. Its certified compatibility with Mitsubishi CNC and drive systems guarantees straightforward integration and stable servo performance. Combined with high structural stiffness and effective thermal management, it is ideal for workshops seeking to enhance capability and uptime on Mitsubishi-controlled machines.

Core Performance Advantages

- Dual-Winding Flexibility for Optimized Machining

- Star (Y) Connection: 22 kW / 210 N·m – ideal for heavy roughing, deep cuts, and tough materials like hardened steel and castings.

- Delta (Δ) Connection: 26 kW / 82.7 N·m – suited for high-efficiency milling and semi-finishing operations.

- Guaranteed Mitsubishi Compatibility

Equipped with a Mitsubishi serial encoder (GEL 2444M) and fully compatible with M800/M80/E80/C80 series CNC and MDS-E/EH/EJ/EM/EMH-SP series drives. Enables plug-and-play integration, reliable communication, and precise motion control. - High Rigidity for Stable Precision

Radial stiffness of 1000 N/µm and axial stiffness of 500 N/µm minimize vibration and deflection, ensuring accuracy and fine surface finish even under heavy loads. - Secure BBT50 Toolholding

BBT50 taper combined with a strong drawbar force (15,000 ± 2,000 N) ensures firm tool retention and efficient power transmission for large-diameter tools. - Effective Cooling System

High-flow coolant (>16 L/min) with cooling capacity >3 kW maintains thermal stability, protecting spindle accuracy and longevity during continuous operation. - Versatile Mounting Orientation

Designed for both vertical and horizontal installation, offering layout flexibility for different machine configurations.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model | A2002051 |

| Housing Diameter | 230 mm | |

| Mounting Orientation | Vertical or Horizontal | |

| Power & Performance | Motor Configuration | Dual Winding (Y/Δ) |

| Rated Power (Y / Δ) | 22 kW (Y) / 26 kW (Δ) | |

| Rated Torque (Y / Δ) | 210 N·m (Y) / 82.7 N·m (Δ) | |

| Maximum Speed | 6,000 rpm | |

| Axial / Radial Stiffness | 500 N/µm / 1000 N/µm | |

| Tool Interface | Tool Holder | BBT50 |

| Control & Drive | Compatible CNC System | Mitsubishi M800/M80/E80/C80 Series |

| Compatible Drive Series | MDS-E/EH/EJ/EM/EMH-SP | |

| Encoder | Mitsubishi Serial (GEL 2444M) | |

| Precision & Build | Taper Runout | ≤ 2.0 µm @ 25mm; ≤ 8.0 µm @ 300mm |

| Bearing System | 7018 × 4, N1012 × 1 (Grease Lubrication) | |

| Dynamic Balance Grade | G0.4 | |

| Clamping & Signals | Drawbar Force | 15,000 ± 2,000 N |

| Tool Change Signal | PNP / NO | |

| Cooling & Pressure | Spindle Cooling | Coolant >16 L/min, >3 kW, max 30°C inlet |

| Tool Coolant Pressure | 7 bar | |

| Air Seal Pressure | 2–7 bar | |

| Clean Air Pressure | 2–7 bar | |

| Tool Clamp Air Pressure | 4–7 bar | |

| Tool Release Oil Pressure | 5–7 MPa | |

| Physical & Support | Net Weight | 156 kg |

| Warranty | 1 Year |

Primary Applications

This spindle is ideally suited for:

- Heavy-duty milling and roughing of steels, castings, and welded structures.

- Large mold and die machining.

- Manufacturing of components for energy, heavy machinery, and transportation sectors.

- Any vertical or horizontal machining center under Mitsubishi control requiring high torque and rigid performance.

Value Proposition

The A2002051 offers Mitsubishi users a versatile and powerful spindle solution that adapts to varied machining demands. With certified compatibility, dual-winding flexibility, and robust construction, it maximizes machine productivity, extends tool life, and ensures precision in the most challenging applications. It represents a reliable investment for workshops aiming to elevate their heavy-duty machining capabilities.

Upgrade Your Mitsubishi Machine with Confidence. Contact us to configure the A2002051 spindle for your vertical or horizontal machining center.