HSK-A100 / BBT50 High-Torque & High-Speed Dual-Winding Spindle

305 N·m / 12,000 rpm | 280mm | Flange Mount | 380V | Compatible with Siemens & 3rd-Party Drives

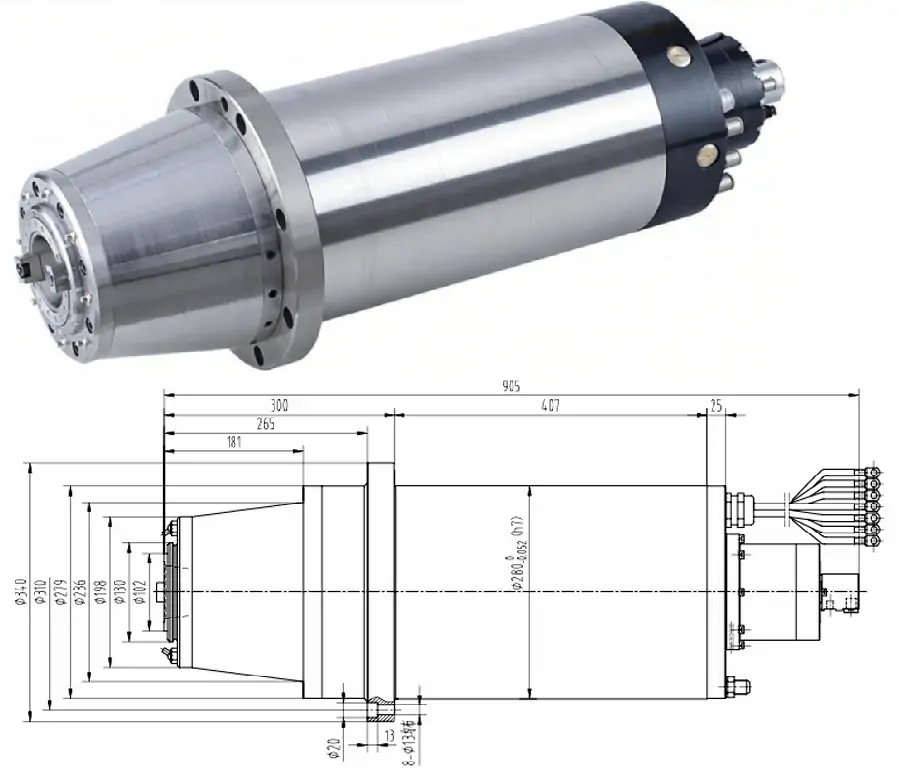

The A2005282 is a powerful and versatile dual-winding electric spindle engineered for heavy-duty horizontal machining centers and gantry mills. Featuring a robust 280mm housing and dual HSK-A100/BBT50 tool interface compatibility, it delivers exceptional flexibility through its dual-winding asynchronous motor. Operators can select high-torque mode (Y-connection: 305 N·m, 1500 rpm max) for demanding roughing, or high-speed mode (Δ-connection: 12,000 rpm, 184 N·m) for efficient milling and finishing. Designed with a flange for vertical mounting orientation, high structural rigidity, and optimized thermal management, it is an ideal performance upgrade for 380V systems using Siemens or other third-party drives alongside its native Mitsubishi encoder interface.

Technical Overview

This spindle is a strategic solution for workshops requiring both immense cutting force and high-speed capability in a single unit. Its core design balances massive torque for heavy stock removal with the speed needed for productivity, all within a rigid, thermally stable platform. The combination of standard Mitsubishi serial encoder compatibility and 380V/6-pole asynchronous motor design ensures easy integration and reliable performance with a wide range of industrial drive systems, maximizing application versatility.

Core Performance Advantages

- Dual-Winding Operational Flexibility: Switch between two optimized performance profiles to match the machining task.

- Star (Y) Connection: Delivers 305 N·m of high torque at 18.5 kW, engineered for stable roughing, deep slotting, and machining of hardened steels, heavy castings, and titanium.

- Delta (Δ) Connection: Provides 12,000 rpm high speed and 26 kW of power, ideal for high-efficiency milling, semi-finishing, and operations requiring high surface finish.

- High Rigidity & Stability for Precision: The large 280mm housing and robust bearing arrangement (7018 × 4 front, N1012 × 1 rear) provide a solid foundation that minimizes vibration and deflection under heavy loads, ensuring part accuracy and superior surface finish.

- Optimized Thermal Management: A dedicated high-flow cooling system (>20 L/min, >3.5 kW cooling capacity) effectively controls operational heat, minimizing thermal growth and protecting precision and bearing life during extended production runs.

- Broad Drive System Compatibility: The 380V, 6-pole asynchronous motor design is specifically configured for compatibility not only with Mitsubishi systems but also with Siemens and other third-party drives, offering greater integration flexibility for machine builders and retrofits.

- Dual Tool Interface & Secure Clamping: Supports both HSK-A100 and BBT50 tool holders, providing flexibility for existing tooling. The hydraulic tool change system (5-7 MPa) ensures reliable, high-force clamping for maximum tool security.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model / Order No. | A2005282 |

| Housing Diameter | 280 mm | |

| Mounting Orientation | Vertical (Flange Mount) | |

| Motor Type | Asynchronous (Induction) | |

| Motor Pole Number | 6 | |

| Power & Performance | Motor Configuration | Dual Winding (Y/Δ) |

| Rated Power (Y / Δ) | 18.5 kW (Y) / 26 kW (Δ) | |

| Rated Torque (Y / Δ) | 305 N·m (Y) / 184 N·m (Δ) | |

| Rated Speed (Y / Δ) | 550 rpm (Y) / 1350 rpm (Δ) | |

| Maximum Speed (Y / Δ) | 1500 rpm (Y) / 12000 rpm (Δ) | |

| Rated Voltage | 380 V | |

| Rated Current (Y / Δ) | 76 A (Y) / 85 A (Δ) | |

| Tool Interface | Tool Holder | HSK-A100 / BBT50 |

| Control & Feedback | Encoder | Mitsubishi Serial |

| Precision & Build | Bearing System | Front: 7018 × 4, Rear: N1012 × 1 |

| Lubrication | Grease | |

| Clamping & Cooling | Tool Change Method | Hydraulic (5-7 MPa) |

| Spindle Cooling | Liquid Coolant (>20 L/min, >3.5 kW) | |

| Center Through-Tool Coolant | Optional | |

| Physical Data | Net Weight | 300 kg |

Primary Applications

This high-performance spindle is ideally suited for:

- Heavy-duty machining on horizontal machining centers and gantry mills.

- Roughing and finishing of large steel plates, weldments, and castings.

- Manufacturing of large molds, dies, and structural components for energy, aerospace, and heavy machinery.

- Any application requiring a versatile spindle capable of both high-torque and high-speed operations on 380V platforms.

Value Proposition

The A2005282 provides machine shops and builders with a formidable and flexible spindle solution that breaks the compromise between torque and speed. Its dual-winding design, high rigidity, and broad drive compatibility make it a cost-effective and powerful upgrade path, capable of handling your most challenging materials and complex parts with confidence and precision.

Equip Your Horizontal Machining Center or Gantry Mill for Maximum Versatility. Contact our engineering team to discuss integrating the A2005282 High-Torque/High-Speed Spindle into your system.