A2001961 High-Torque Dual-Winding Spindle with HSK-A100

Heavy-Duty Power for Large Tool Machining | 81 N·m Torque | 22 kW Power

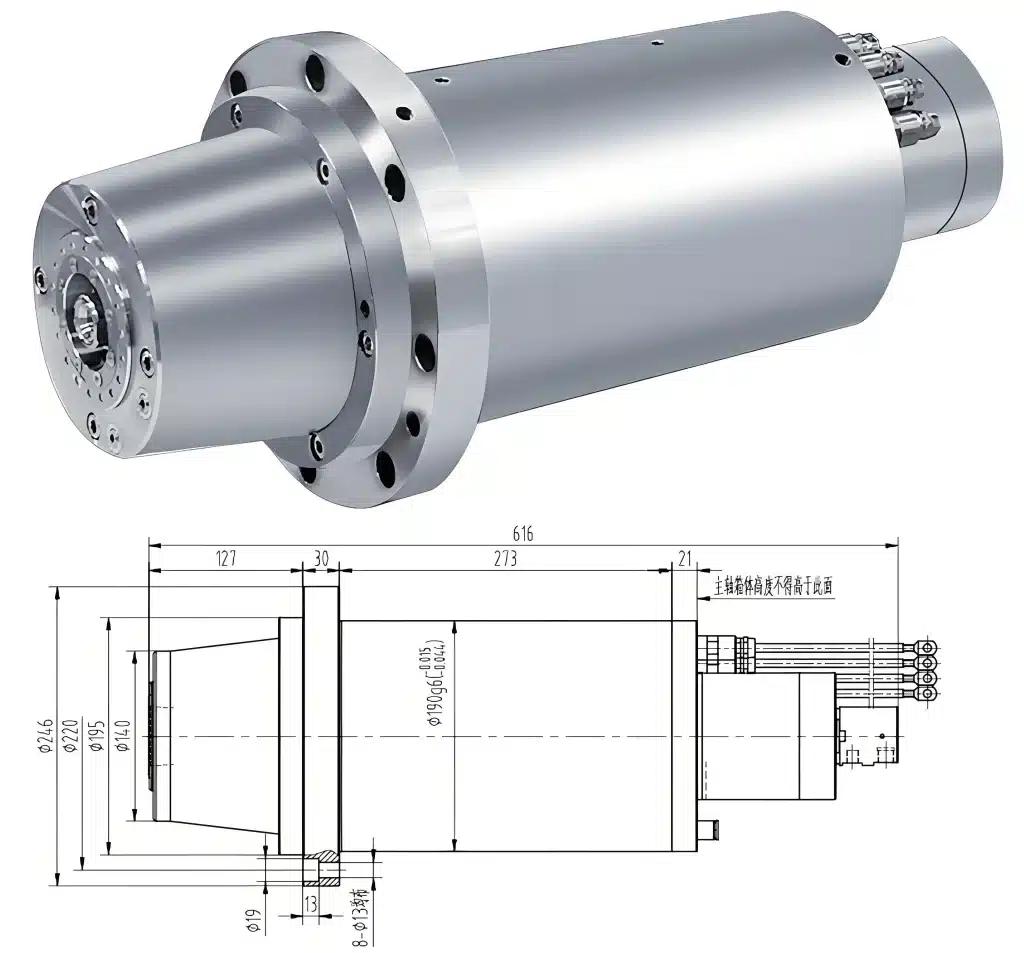

The A2001961 is a robust, high-torque electric spindle engineered for heavy-duty milling applications requiring the use of large-diameter tools and substantial cutting force. Built around a formidable HSK-A100 tool interface within a 190mm housing, its dual-winding (Y/Δ) motor offers strategic flexibility: delivering 81 N·m of high torque for challenging materials or 22 kW of power for efficient high-feed operations. Featuring an exceptionally high drawbar force of 45,000 N for utmost tool security, this vertical-mount spindle is designed for stability and productivity in large-part machining on gantry mills and powerful vertical machining centers.

Technical Overview

This spindle is purpose-built for shops that utilize large face mills, slotting cutters, and other substantial tooling on tough materials. The HSK-A100 interface provides the rigidity and precision necessary for heavy-load power transmission. The dual-winding design allows operators to prioritize either immense cutting force or maximum power efficiency, making it a versatile core component for demanding industrial milling tasks.

Core Performance Advantages

- Dual-Winding Operational Flexibility:

- Star (Y) Connection: Generates 81 N·m of high torque at 18.5 kW, ideal for stable machining of hard steels, stainless steels, and heavy castings where low-speed, high-force cutting is required.

- Delta (Δ) Connection: Provides 22 kW of power and 35 N·m torque, optimized for high-efficiency milling and semi-finishing operations at higher rotational speeds.

- Heavy-Duty HSK-A100 Tool Interface: The large HSK-A100 taper is specifically designed for high-power transmission and maximum rigidity with large-diameter tools, ensuring precise and stable machining under heavy loads.

- Extreme Tool Clamping Security: An outstanding drawbar force of 45,000 N (± 2000 N) guarantees the securest possible tool retention, eliminating the risk of tool slippage during the most aggressive cutting conditions.

- Designed for Stability: Excellent radial stiffness (450 N/µm) minimizes deflection during side-cutting operations, contributing to part accuracy and surface finish quality.

- Integrated for Automation: Configured with standard PNP/NO tool change signals and comprehensive air sealing/purging functions for reliable integration into automated machining environments.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model | A2001961 |

| Housing Diameter | 190 mm | |

| Mounting Orientation | Vertical | |

| Power & Performance | Motor Configuration | Dual Winding (Y/Δ) |

| Rated Power (Y / Δ) | 18.5 kW (Y) / 22 kW (Δ) | |

| Rated Torque (Y / Δ) | 81 N·m (Y) / 35 N·m (Δ) | |

| Maximum Speed | 10,000 rpm | |

| Axial / Radial Stiffness | 150 N/µm / 450 N/µm | |

| Tool Interface & Drive | Tool Holder | HSK-A100 |

| Encoder Signal | Sine Wave / 200-tooth | |

| Precision & Construction | Taper Runout | ≤ 2.0 µm @ 25mm |

| Face Runout | ≤ 2.0 µm | |

| Bearing System | 71920 × 2, N1012 × 1 (Grease) | |

| Dynamic Balance | G0.4 | |

| Clamping & Automation | Drawbar Force | 45,000 ± 2,000 N |

| Tool Change Signal | PNP / NO | |

| Tool Release Pressure | 5 – 7 MPa | |

| Cooling & Auxiliary | Spindle Body Cooling | Oil/Water Coolant (>10 L/min, >2 kW) |

| Air Seal / Purge Pressure | 2 – 7 bar | |

| Physical Data & Warranty | Net Weight | 95 kg |

| Warranty | 1 Year |

Primary Applications

This spindle is engineered for large-scale, heavy-load machining, including:

- Heavy face milling and roughing of large steel plates, weldments, and castings.

- Deep slotting and profiling operations on large components in the energy, railway, and heavy machinery sectors.

- Machining of large molds and dies where large-diameter tools are used for efficient material removal.

- General heavy-duty milling on large gantry and vertical machining centers.

Value Proposition

The A2001961 provides the perfect combination of a large, rigid tool interface, extremely high clamping force, and configurable power/torque output. It is designed to handle the most demanding jobs with large tooling, offering reliability, security, and the flexibility to adapt to different materials and machining strategies, thereby maximizing the capability of your heavy-duty machine tool.

Power Your Largest Tools with Confidence. Contact our engineering team to discuss integrating the A2001961 HSK-A100 spindle into your heavy-duty milling setup.