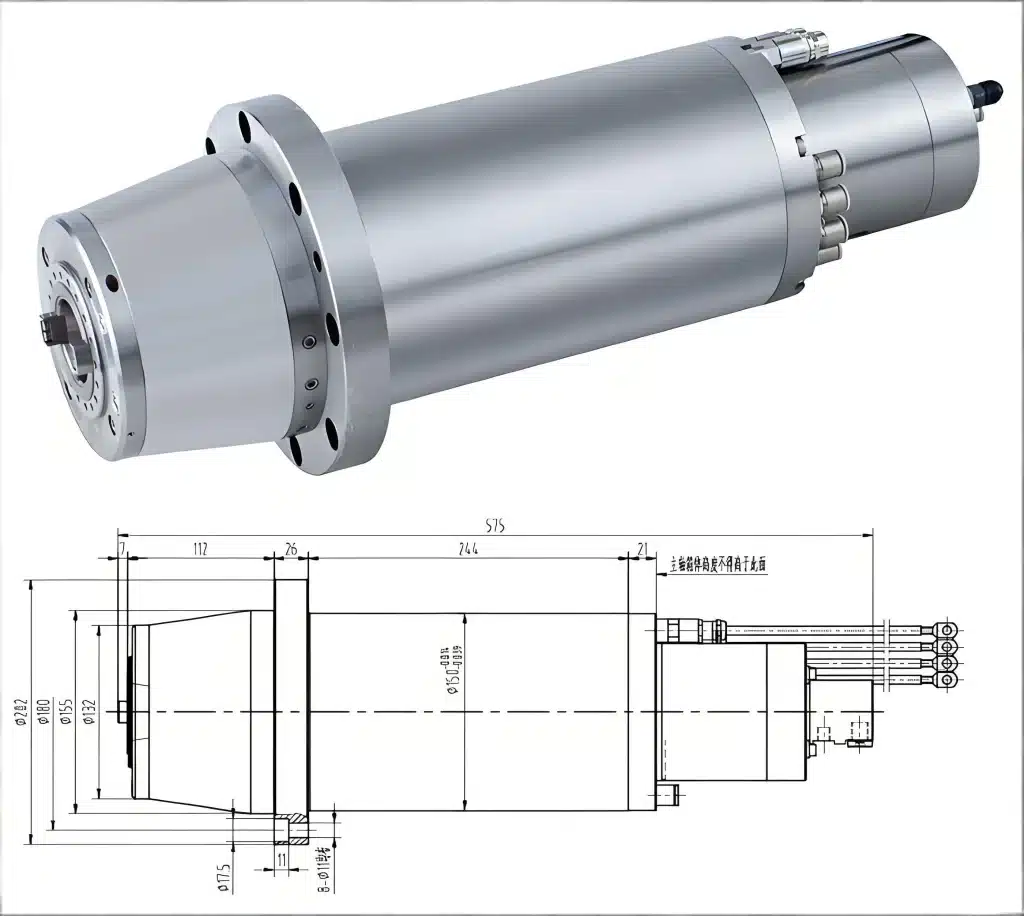

A2003531 High-Power Dual-Winding Spindle for Heavy-Duty Gantry & Machining Centers

HSK-A63 | 20 kW | 39.6 N·m | Dual Winding (Y/Δ) for Fanuc & Third-Party Drives

The A2003531 is a premium, high-rigidity electric spindle engineered for heavy-duty milling, engraving, and large-part machining on gantry mills, vertical machining centers, and high-power CNC mills. Featuring a robust HSK-A63 tool interface and a 380V dual-winding motor, it delivers up to 20 kW of power and 39.6 N·m of torque, offering dual-mode versatility for both high-torque roughing and high-power semi-finishing through its Star (Y) and Delta (Δ) connections. Designed for exceptional stability, low thermal growth, and broad drive compatibility, it is the ideal spindle for demanding industrial applications.

Technical Overview

Built to handle challenging materials and large workpieces, the A2003531 combines immense cutting force with precision engineering. Its dual-winding motor design allows operators to optimize performance for specific tasks—maximizing torque for difficult alloys or maximizing power and speed for efficient material removal. Compatible with Fanuc and other third-party drives, it provides flexible integration into a wide range of high-performance machine tools.

Core Performance Advantages

- Dual-Winding Operational Flexibility:

- Star (Y) Connection: Delivers 39.6 N·m of high torque at 15 kW for heavy roughing, deep cavity milling, and machining of hardened steels, stainless steels, and titanium.

- Delta (Δ) Connection: Provides 20 kW of full power and 24.8 N·m torque for high-efficiency semi-finishing, face milling, and high-speed machining of aluminum and composites.

- Exceptional Rigidity & Stability: High radial stiffness (600 N/µm) and axial stiffness (200 N/µm) ensure minimal deflection and vibration, enabling accurate, chatter-free machining even under extreme loads.

- Optimized Thermal Management: A high-flow liquid cooling system (>10 L/min) effectively controls heat, reducing thermal elongation to maintain precision during extended production runs.

- Heavy-Duty Tool Clamping: Equipped with an HSK-A63 tool holder and an extremely high drawbar force (18,000 ± 2,000 N) for secure, reliable tool retention in heavy cutting conditions.

- Broad Drive Compatibility: The 380V dual-winding design allows seamless integration with Fanuc and other major third-party drive systems, offering installation flexibility and performance optimization.

- Superior Precision & Smooth Operation: Precision-ground taper (runout ≤2.0 µm), G0.4 dynamic balance grade, and low vibration (≤1.0 mm/s) ensure smooth running, fine surface finishes, and extended tool life.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Spindle Designation | Electric Spindle |

| Model | A2003531 | |

| Tool Holder | HSK-A63 | |

| Bearing Specification | 7009 × 2, 7013 × 3 | |

| Lubrication | Grease | |

| Mounting Orientation | Vertical | |

| Drive Method | Built-in Motor | |

| Adapter Drive | FANUC & Third-Party | |

| Encoder Signal | Sine Wave / 160-tooth | |

| Tool Change Signal | PNP / NO | |

| Dynamic Balance Grade | G0.4 | |

| Warranty | 1 Year | |

| Spindle Weight | 56 kg | |

| Packing Weight (Wooden Case) | 7 kg | |

| Performance | Maximum Speed | 18,000 rpm |

| Radial Stiffness | 600 N/µm | |

| Axial Stiffness | 200 N/µm | |

| Taper Runout | ≤ 2.0 µm (at 25mm); ≤ 8.0 µm (at 300mm) | |

| Face Runout | ≤ 2.0 µm | |

| Vibration Velocity | ≤ 1.0 mm/s | |

| Rated Power (Y / △) | 15 kW / 20 kW | |

| Rated Torque (Y / △) | 39.6 N·m / 24.8 N·m | |

| Drawbar Force | 18000 ± 2000 N | |

| Operating Conditions | Cooling Method | Oil/Water Coolant Flow >10 L/min, Cooling Power >2.0 kW, Max. Inlet Temp. 30°C |

| Air Seal Pressure | 2 – 7 bar | |

| Clean Air Pressure | 2 – 7 bar | |

| Tool Release Oil Pressure | 5 – 7 MPa | |

| Tool Clamp Air Pressure | 4 – 7 bar |

Primary Applications

This spindle is engineered for large-scale, high-power machining, including:

- Heavy-duty milling on gantry machining centers and large vertical mills.

- Roughing and semi-finishing of large molds, dies, and aerospace structural components.

- Deep cavity machining and high-efficiency face milling.

- Machining of high-strength materials such as hardened steel, titanium, and Inconel.

Value Proposition

The A2003531 transforms large machine tools into highly productive systems by offering unmatched flexibility, power, and rigidity through its dual-winding design. It enables faster material removal, ensures accuracy through superior stiffness, and provides reliable, continuous performance for the most challenging industrial applications.

Power Your Most Demanding Machining Tasks. Contact our engineering team today to discuss integration options and configure the A2003531 High-Power Dual-Winding Spindle for your gantry, vertical, or large machining center.