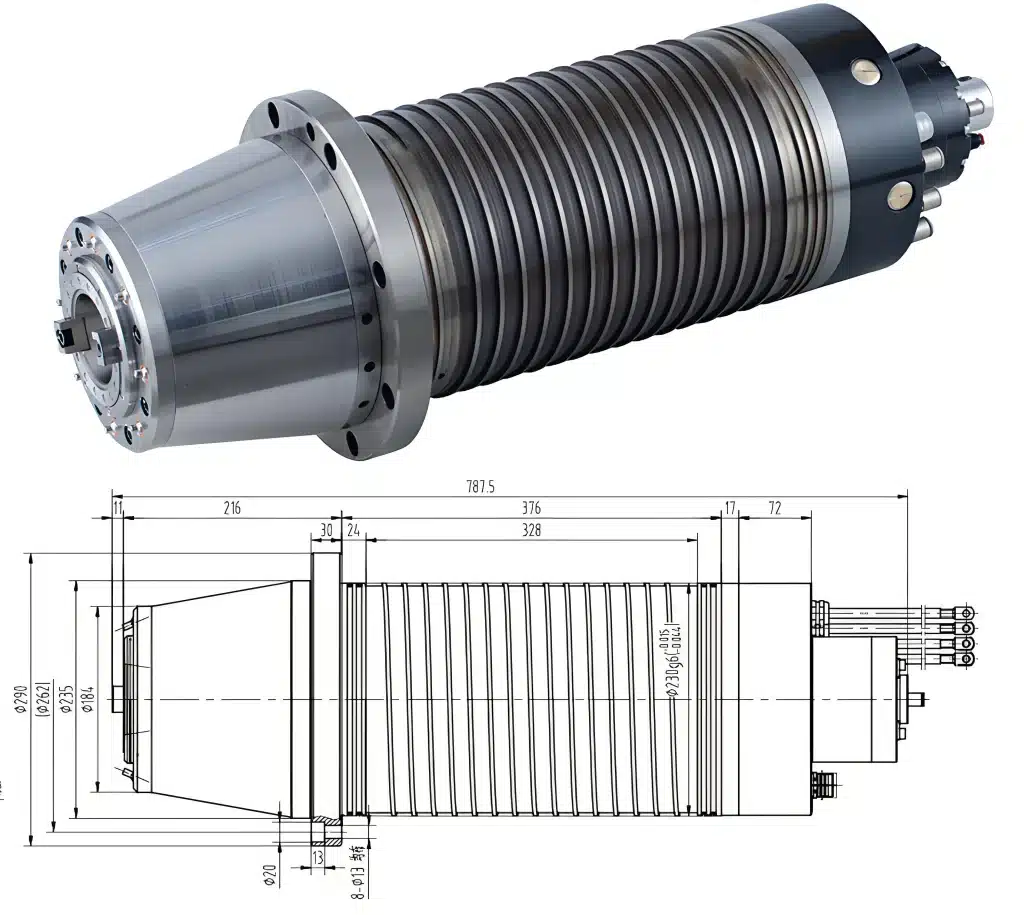

A2004191 Ultra-High-Torque Short-Nose Spindle with HSK-A100

206 N·m Torque | 35 kW | Engineered for Maximum Rigidity & Access in Heavy-Duty Machining

The A2004191 represents the pinnacle of heavy-duty spindle design, engineered for the most demanding milling applications on large gantry mills, floor-type boring machines, and powerful machining centers. Built with a massive 230mm diameter and a robust HSK-A100 tool interface, its dual-winding (Y/Δ) motor unleashes a colossal 206 N·m of torque for conquering the toughest materials, while maintaining 35 kW of power. The innovative short-nose design provides superior workpiece access, and when combined with exceptional rigidity (1000 N/µm radial stiffness), an immense 45,000 N drawbar force, and integrated high-pressure coolant, it defines a new standard for productivity and capability in large-part manufacturing.

Technical Overview

This spindle is engineered as a true powerhouse, prioritizing extreme torque delivery and structural integrity above all else. The “short-nose” configuration minimizes overhang, bringing the tool closer to the bearing support for unmatched rigidity and allowing access to deep cavities or confined workspaces on large components. Designed for versatile horizontal or vertical installation, it is equipped with a comprehensive cooling system to manage the significant thermal loads of continuous, high-power cutting, making it the ultimate core component for heavy industrial machining.

Core Performance Advantages

- Class-Leading Torque for Unmatched Cutting Force: In Star (Y) connection, it delivers a monumental 206 N·m of torque, providing the relentless power needed for aggressive roughing, deep slotting, and stable machining of hardened steels, titanium alloys, and heavy castings.

- Short-Nose Design for Superior Rigidity & Access: The reduced front-end overhang significantly increases the spindle’s effective stiffness and allows tools to reach deeper into workpieces or work around fixtures—a critical advantage in mold machining and complex part production.

- Extreme Structural Integrity: Record-setting radial stiffness of 1000 N/µm and axial stiffness of 500 N/µm create an virtually immovable platform, eliminating vibration and deflection to ensure supreme accuracy and surface finish under extreme loads.

- Ultra-Secure HSK-A100 Interface & Clamping: The HSK-A100 taper is designed for maximum power transmission, paired with an industry-leading drawbar force of 45,000 N to guarantee absolute tool security during the heaviest cuts.

- Advanced Integrated Cooling: A high-flow spindle cooling system (>16 L/min) works in tandem with high-pressure through-spindle coolant (7 MPa) to effectively manage heat at the tool tip, enabling efficient deep-hole drilling and extended tool life.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model | A2004191 |

| Housing Diameter | 230 mm | |

| Mounting Orientation | Horizontal or Vertical | |

| Nose Design | Short-Nose | |

| Power & Performance | Motor Configuration | Dual Winding (Y/Δ) |

| Rated Power (Y / Δ) | 35 kW (Y & Δ) | |

| Rated Torque (Y / Δ) | 206 N·m (Y) / 83.4 N·m (Δ) | |

| Maximum Speed | 12,000 rpm | |

| Axial / Radial Stiffness | 500 N/µm / 1000 N/µm | |

| Tool Interface & Drive | Tool Holder | HSK-A100 |

| Encoder Signal | Sine Wave / 200-tooth | |

| Precision & Construction | Taper Runout | ≤ 2.0 µm @ 25mm |

| Bearing System | 71918 × 4, N1012 × 1 (Grease) | |

| Dynamic Balance | G0.4 | |

| Clamping & Automation | Drawbar Force | 45,000 ± 2,000 N |

| Tool Change Signal | PNP / NO | |

| Cooling Systems | Spindle Body Cooling | Oil/Water Coolant (>16 L/min, >3 kW) |

| Center Through Coolant (CTC) | Max Pressure: 7 MPa | |

| Physical Data & Warranty | Net Weight | 167 kg |

| Warranty | 1 Year |

Primary Applications

This spindle is engineered for the largest and most challenging machining tasks:

- Heavy roughing and finishing of large forging dies, mold bases, and industrial tooling.

- Machining of massive structural components for energy (wind turbine hubs, press frames), aerospace, and marine industries.

- Deep cavity milling in large molds where the short-nose design provides crucial access.

- High-productivity face milling and boring on floor-type and gantry machining centers.

Value Proposition

The A2004191 is more than a spindle; it is a capability transformer for your most powerful machine tools. It delivers unparalleled torque and rigidity in a configuration that maximizes workspace accessibility. This combination allows manufacturers to tackle their most ambitious projects with faster metal removal rates, superior accuracy, and the confidence to machine complex features in heavy, high-value workpieces.

Equip Your Machine for the Most Demanding Projects. Contact our engineering team to discuss integrating the A2004191 Ultra-High-Torque Short-Nose Spindle into your heavy-duty machining platform.