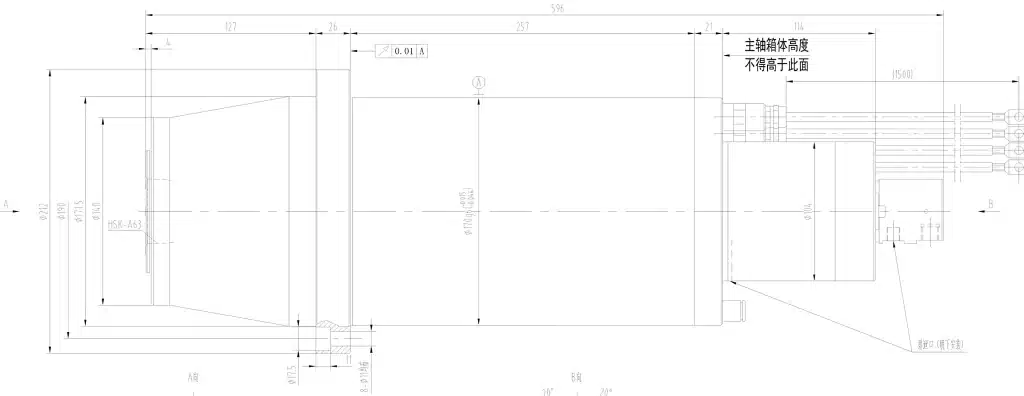

A2004471 High-Torque Machining Spindle

22 kW | 71.2 N·m | HSK-A63 | Versatile Power for Heavy-Duty Horizontal & Vertical Applications

The A2004471 is a formidable, high-torque electric spindle engineered to deliver exceptional cutting force and rigidity for heavy-duty milling and boring operations. Featuring a robust 170mm housing and an HSK-A63 tool interface, it generates a massive 71.2 N·m of torque from a 22 kW power source, making it ideal for demanding material removal on tough alloys. Designed for versatile horizontal or vertical installation and equipped with a 7 MPa through-spindle coolant system, this 300V single-winding spindle offers reliable, high-performance machining for large workpieces on gantry mills, boring machines, and high-power machining centers.

Technical Overview

Built to provide unwavering stability under extreme loads, the A2004471 focuses on delivering high torque at a practical power rating for efficient heavy cutting. Its design emphasizes maximum rigidity, effective heat dissipation, and flexible integration. The 300V single-winding motor ensures compatibility with specific industrial drive configurations, while its dual-orientation mounting capability offers machine builders and shops exceptional application versatility.

Core Performance Advantages

- Exceptional Torque Density: Delivers a powerful 71.2 N·m of torque from a 22 kW motor, providing outstanding cutting force for aggressive roughing, deep slotting, and stable machining of hardened steels, stainless steels, and castings.

- Extreme Structural Rigidity: An impressive radial stiffness of 900 N/µm and axial stiffness of 300 N/µm form an ultra-stable platform that minimizes deflection, ensures dimensional accuracy, and enables superior surface finishes under heavy loads.

- Versatile Mounting & Integration: Engineered for both horizontal and vertical installation, this spindle provides maximum flexibility for integration into various machine tool configurations, from horizontal machining centers (HMCs) to large vertical mills.

- Advanced Thermal & Chip Management: The combination of high-flow spindle jacket cooling and a high-pressure through-spindle coolant (7 MPa) system effectively controls cutting zone temperature, improves chip evacuation for deep-hole operations, and extends tool life.

- Robust & Reliable Design: A heavy-duty bearing system (71910×2 / 71914×4) and a very high drawbar force (18,000 ± 2,000 N) guarantee secure tool clamping and ensure dependable, long-term performance in continuous production environments.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model | A2004471 |

| Housing Diameter | 170 mm | |

| Mounting Orientation | Horizontal or Vertical | |

| Power & Performance | Rated Power | 22 kW |

| Rated Torque | 71.2 N·m | |

| Maximum Speed | 18,000 rpm | |

| Axial / Radial Stiffness | 300 N/µm / 900 N/µm | |

| Tool Interface & Drive | Tool Holder | HSK-A63 |

| Motor & Voltage | 300 V, Single Winding | |

| Encoder Signal | Sine Wave / 160-tooth | |

| Precision & Construction | Taper Runout | ≤ 2.0 µm @ 25mm |

| Face Runout | ≤ 2.0 µm | |

| Bearing System | 71910 × 2, 71914 × 4 (Grease) | |

| Dynamic Balance | G0.4 | |

| Clamping & Automation | Drawbar Force | 18,000 ± 2,000 N |

| Tool Change Signal | PNP / NO | |

| Tool Release Pressure | 5 – 7 MPa | |

| Cooling Systems | Spindle Body Cooling | Oil/Water Coolant (>10 L/min, >2 kW) |

| Center Through Coolant (CTC) | Max Pressure: 7 MPa | |

| Air Seal / Purge | 2 – 7 bar | |

| Physical Data & Warranty | Net Weight | 86 kg |

| Warranty | 1 Year |

Primary Applications

This high-torque spindle is ideally suited for:

- Heavy-duty milling and boring of large components in the energy, construction, and mining equipment sectors.

- Machining of high-strength materials such as alloy steels, titanium, and heavy castings on horizontal boring mills.

- Deep cavity and face milling operations on large vertical machining centers (VMCs) and gantry mills.

- Production of large molds, dies, and industrial tooling where high torque and stability are critical.

Value Proposition

The A2004471 spindle provides an optimal balance of high torque and practical power for cost-effective heavy machining. Its flexible mounting options and robust construction make it a reliable and versatile core component, designed to enhance the capability and productivity of your machine tools for the most challenging industrial workpieces.

Configure Your Heavy-Duty Machining Solution. Contact our engineering team to discuss the integration of the versatile A2004471 High-Torque Spindle into your horizontal or vertical machining platform.