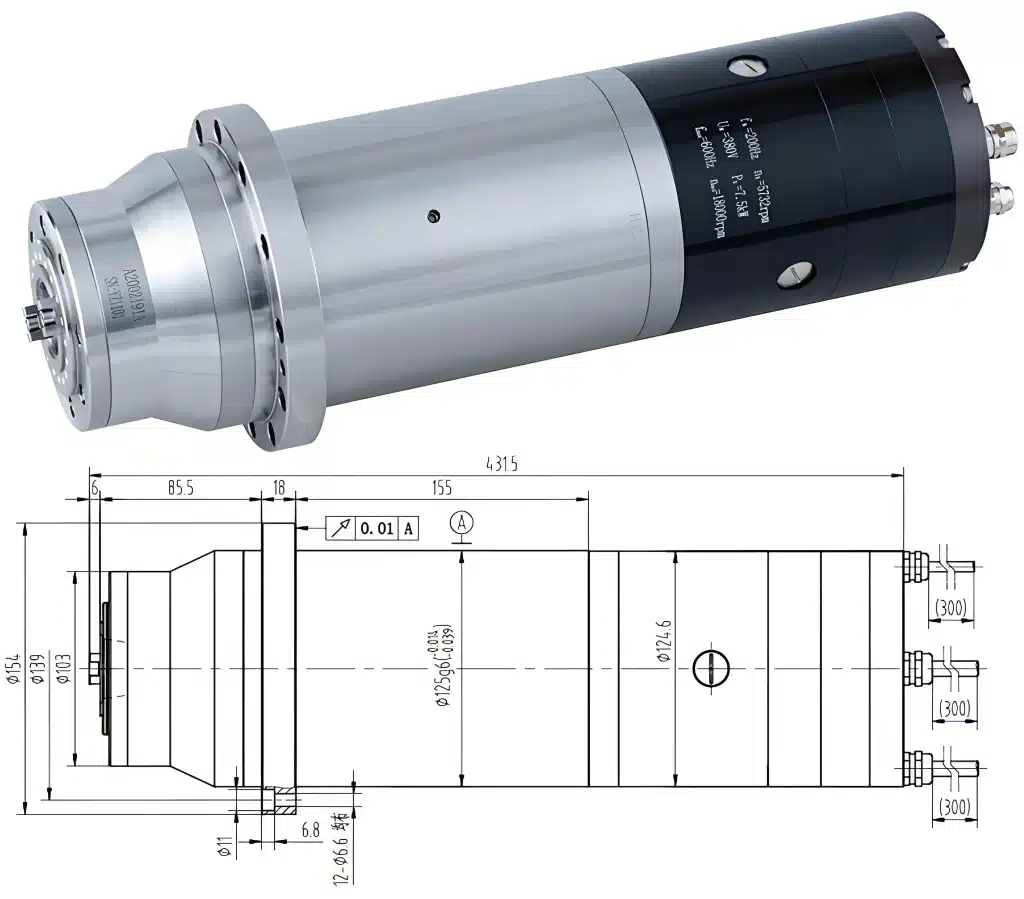

A2005121 High-Torque Machining Spindle

125mm Flange, 12.5 N·m Powerhouse for Heavy-Duty Cutting with BT30 Tool System

The A2005121 is a robust and rigid electric spindle engineered for heavy-duty milling operations requiring substantial cutting force and exceptional stability. Featuring a 125mm flange diameter, a high-torque motor delivering 12.5 N·m, and a standard BT30 tool holder with a drive key, it is built to excel in demanding machining applications on steel, stainless steel, and cast iron. Its versatile design supports multiple feedback options to seamlessly integrate into a wide range of CNC control systems.

Product Overview

Designed for vertical installation in machining centers, the A2005121 prioritizes power transmission and structural integrity. The high radial stiffness (300 N/µm) and substantial drawbar force (2500-3000 N) ensure minimal deflection and secure tool clamping during aggressive cuts. This spindle is the ideal solution for manufacturers who need reliable, high-torque performance for roughing and semi-finishing operations.

Core Features & Advantages

- High Torque for Heavy Cuts: A powerful 7.5 kW motor generates 12.5 N·m of continuous torque, enabling efficient material removal with larger tools and deeper cuts.

- Exceptional Rigidity & Stability: Outstanding radial stiffness (300 N/µm) and axial stiffness (100 N/µm) provide a solid foundation for accurate and vibration-free machining, even under significant load.

- Versatile Feedback Options (Configurable): Can be supplied with your choice of encoder to match your CNC system:

- Square Wave Encoder (1024-line): Standard, reliable feedback for most CNC applications.

- Sine Wave Encoder: For systems requiring high-resolution feedback for ultra-smooth motion.

- No Encoder: For use with sensorless vector control variable-frequency drives (VFDs).

- Robust Mechanical Design: Features a BT30 tool holder with a drive key for positive torque transmission, a heavy-duty bearing system (7008×2 / 71910×3), and a 125mm flange for secure mounting.

- Effective Thermal Management: Requires an external oil or water cooling system (>6 L/min, >1 kW chiller) to maintain consistent performance and precision during prolonged operation.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General & Ordering | Spindle Designation | Motorized Spindle |

| Model | A2005121-PNP | |

| Mounting Orientation | Vertical | |

| Tool Holder | BT30 (with Flange & Drive Key) | |

| Warranty | 1 Year | |

| Performance | Maximum Speed | 18,000 rpm |

| Rated Power | 7.5 kW | |

| Rated Torque | 12.5 N·m | |

| Radial Stiffness | 300 N/µm | |

| Axial Stiffness | 100 N/µm | |

| Taper Runout | ≤ 2.0 µm @ 25mm; ≤ 8.0 µm @ 250mm | |

| Dynamic Balance Grade | G0.4 | |

| Drawbar Force | 2500 – 3000 N | |

| Mechanical Construction | Bearing Specification | 7008 × 2, 71910 × 3 |

| Lubrication | Grease | |

| Spindle Weight | 25 kg | |

| Drive Method | Built-in Motor | |

| System Integration (Configurable) | Encoder Signal | Customer Selectable: • Square Wave / 1024 PPR • Sine Wave • No Encoder |

| Tool Change Signal | PNP / NO (Normally Open) | |

| Cooling & Pneumatics | Cooling Method | Oil or Water Coolant Flow > 6 L/min, Cooling Power > 1 kW, Max. Inlet Temp 30°C |

| Air Seal Pressure | 2 – 7 bar | |

| Clean Air Pressure | 2 – 7 bar | |

| Tool Release Pressure | 5 – 7 bar | |

| Tool Release Air Volume | 184 cm³ |

Primary Applications

This high-torque spindle is perfectly suited for:

- Heavy roughing and milling of steel, stainless steel, and cast iron components.

- Mold base and large cavity machining in tool and die manufacturing.

- General heavy-duty machining on vertical machining centers (VMCs).

- Production environments where process stability and powerful cutting force are prioritized over ultra-high speed.

Configuration & Integration

We understand that integration is key. The A2005121 can be tailored to your control system with the appropriate encoder option. Contact our technical team to specify your requirements for a plug-and-play solution that maximizes your machine’s productivity and capability.

Power Your Heavy-Duty Machining. Contact us today to discuss configuration details and get a tailored quotation for the A2005121 High-Torque BT30 Spindle.