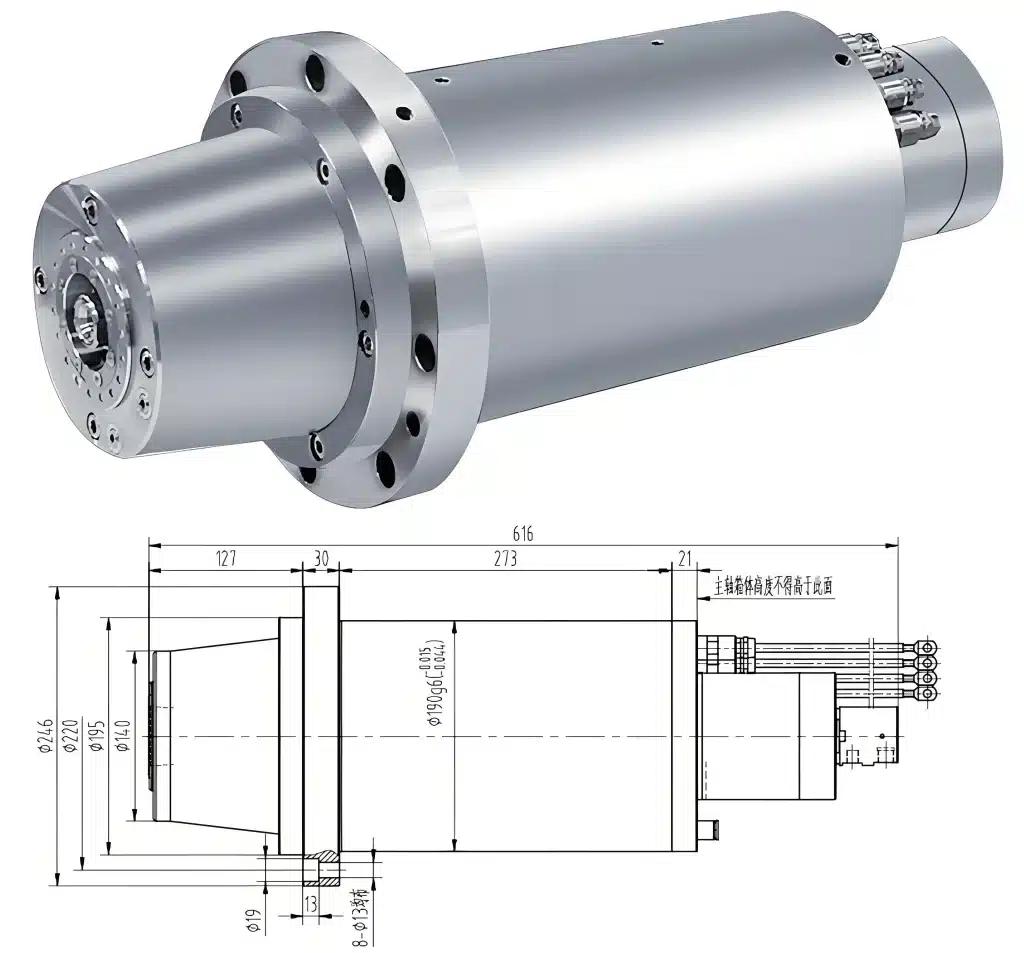

A2005261 High-Torque Spindle for AC Swivel Heads

105 N·m Torque | 30 kW | 190mm HSK-A63 | Engineered for Precision 5-Axis Machining & Heavy-Duty Milling

The A2005261 is a specialized, high-torque electric spindle designed for integration into AC swivel heads (pendulum heads) and angular milling attachments on 5-axis machining centers, gantry mills, and high-performance vertical mills. Built around a robust 190mm housing with an integrated flange and drive flat for precise orientation, it delivers an exceptional 105 N·m of torque from a 30 kW motor. Combining immense cutting force with extreme rigidity (900 N/µm radial stiffness) and integrated 7 MPa through-spindle coolant, it is the ideal solution for stable, accurate machining of complex geometries and tough materials in dynamic multi-axis applications.

Technical Overview

This spindle is engineered specifically for the demands of swivel head and angular head machining, where stability, precision, and power transmission in various orientations are critical. Its single-speed, high-torque design prioritizes consistent performance for heavy cutting in challenging alloys. The specialized mounting flange ensures rigid and repeatable integration into the swivel mechanism, making it a core component for advanced 5-axis contouring and complex part production.

Core Performance Advantages

- Exceptional Torque for Demanding Cuts: Generates a formidable 105 N·m of continuous torque, providing the necessary force for stable roughing, deep cavity milling, and side-cutting of hardened steels, titanium, and Inconel in a swivel head configuration.

- Optimized for Swivel Head Integration: The 190mm housing with a dedicated flange and drive flat ensures secure, accurate, and repeatable mounting within AC swivel head units, maintaining tool center point (TCP) accuracy critical for 5-axis work.

- Extreme Rigidity for Multi-Axis Stability: Ultra-high radial stiffness (900 N/µm) minimizes deflection and vibration during off-center and side-load machining operations, ensuring part accuracy and superior surface finish across complex contours.

- Effective Thermal & Chip Management: A high-flow cooling system (>10 L/min) manages spindle temperature, while the high-pressure through-spindle coolant (7 MPa) enhances chip evacuation in deep pockets and improves tool life, essential for uninterrupted 5-axis machining cycles.

- Robust Construction for Demanding Applications: Features a heavy-duty bearing system (71910×2 / 71914×3) and an extremely high drawbar force (18,000 ± 2,000 N) to guarantee tool security and reliable performance under heavy loads in any orientation.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model | A2005261 |

| Primary Application | AC Swivel Head / Angular Head | |

| Housing Design | 190 mm, with Flange & Drive Flat | |

| Power & Performance | Rated Power | 30 kW |

| Rated Torque | 105 N·m | |

| Maximum Speed | 18,000 rpm | |

| Axial / Radial Stiffness | 300 N/µm / 900 N/µm | |

| Tool Interface & Drive | Tool Holder | HSK-A63 |

| Encoder Signal | Sine Wave / 160-tooth | |

| Precision & Construction | Taper Runout | ≤ 2.0 µm @ 25mm |

| Face Runout | ≤ 2.0 µm | |

| Bearing System | 71910 × 2, 71914 × 3 (Grease) | |

| Dynamic Balance | G0.4 | |

| Clamping & Automation | Drawbar Force | 18,000 ± 2,000 N |

| Tool Change Signal | PNP / NO | |

| Tool Release Pressure | 5 – 7 MPa | |

| Cooling Systems | Spindle Body Cooling | Oil/Water Coolant (>10 L/min, >2 kW) |

| Center Through Coolant (CTC) | Max Pressure: 7 MPa | |

| Air Seal / Purge | 2 – 7 bar | |

| Physical Data & Warranty | Net Weight | 96 kg |

| Warranty | 1 Year |

Primary Applications

This spindle is engineered for advanced, multi-axis heavy-duty machining:

- 5-axis contouring of complex aerospace components (blisks, impellers, structural parts).

- Angular milling and deep cavity machining in large, complex molds and dies.

- Heavy-duty milling on gantry mills and vertical machining centers equipped with swivel/angular head attachments.

- Production of prototypes and high-value parts requiring simultaneous multi-axis movement and high material removal rates.

Value Proposition

The A2005261 is purpose-built to maximize the capability of your 5-axis or angular head setup. It delivers the high torque and exceptional rigidity needed to machine difficult materials efficiently and accurately in a single setup, reducing cycle times and eliminating secondary operations. Its specialized design for swivel head integration ensures reliability and precision, making it a strategic investment for shops specializing in high-value, complex component manufacturing.

Power Your Advanced Multi-Axis Machining. Contact our technical team to discuss integrating the A2005261 High-Torque Swivel Head Spindle into your 5-axis system or angular head unit.