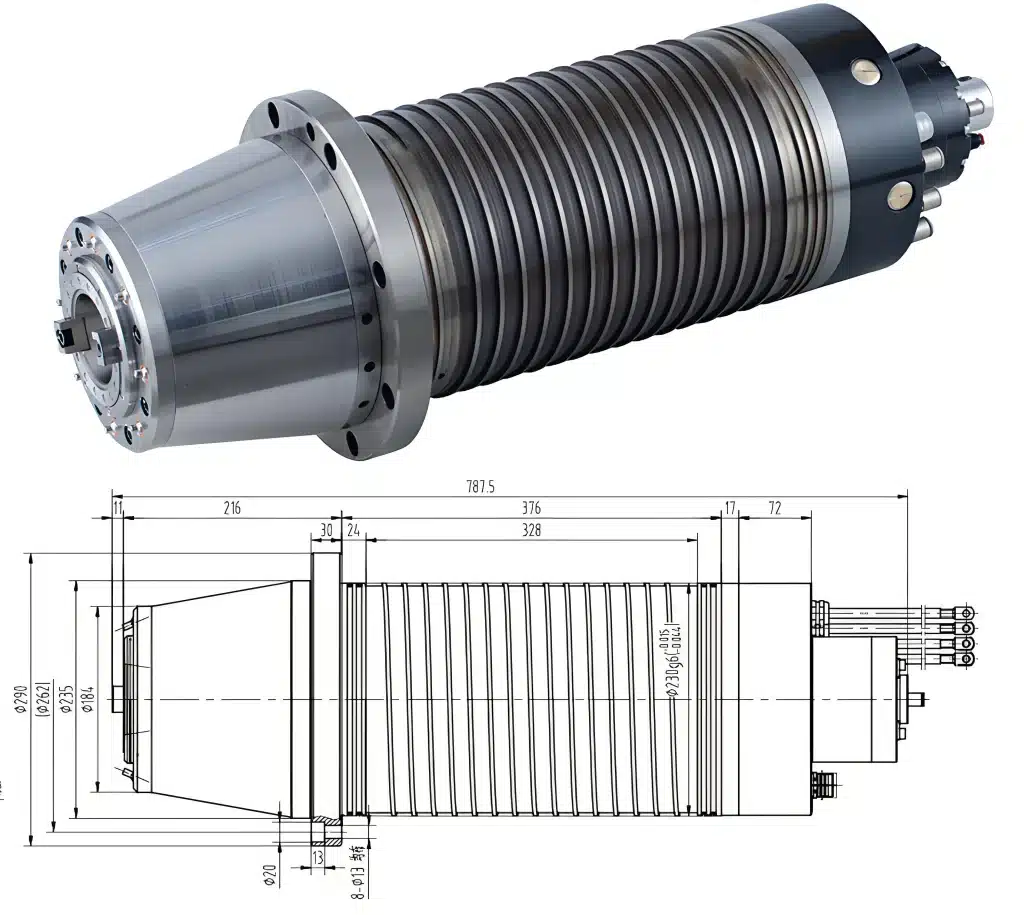

A2005701 High-Torque Dual-Winding Spindle for Mitsubishi Systems

HSK-A100 | 210 N·m Torque | 230mm | Certified for Seamless Mitsubishi Integration

The A2005701 is a formidable, dual-winding electric spindle engineered to deliver exceptional torque and versatility for heavy-duty vertical machining centers and gantry mills within the Mitsubishi control ecosystem. Featuring a robust 230mm housing and an HSK-A100 tool interface, it offers strategic performance flexibility through its dual-winding (Y/Δ) motor, providing either 210 N·m of high torque for challenging materials or 26 kW of power for efficient milling. Pre-configured and certified for Mitsubishi CNC and drive systems, and built with extreme rigidity (1000 N/µm radial stiffness), it guarantees plug-and-play reliability and precision for demanding large-part manufacturing.

Technical Overview

This spindle is designed as a versatile powerhouse for vertical applications, offering machine shops the ability to optimize cutting strategy based on material and operation. Its core strength lies in combining substantial torque output with the assurance of seamless integration into the Mitsubishi automation environment. The certified compatibility eliminates setup complexity, while the high rigidity ensures stable performance under heavy loads, making it an ideal upgrade for high-productivity workshops.

Core Performance Advantages

- Dual-Winding Strategic Flexibility: Enables optimized machining by selecting the ideal performance profile.

- Star (Y) Connection: Delivers a massive 210 N·m of torque at 22 kW, engineered for stable roughing, deep slotting, and machining of hardened steels, titanium, and heavy castings.

- Delta (Δ) Connection: Provides 26 kW of power and 82.7 N·m torque, optimized for high-efficiency milling and semi-finishing operations.

- Guaranteed Mitsubishi Compatibility & Performance: Equipped with a Mitsubishi serial encoder (GEL244M) and fully validated for M800/M80/E80/C80 series CNC and MDS-D/E/EJ/EM/EMH-SP series drives. This ensures flawless communication, simplified commissioning, and reliable, high-performance servo control.

- Extreme Structural Rigidity for Accuracy: Exceptional radial stiffness (1000 N/µm) and axial stiffness (500 N/µm) create an ultra-stable platform that minimizes vibration and deflection, ensuring part accuracy and superior surface finish under extreme cutting forces.

- Ultra-Secure Toolholding for Heavy Loads: The large HSK-A100 taper combined with an immense drawbar force of 45,000 N ensures absolute tool security and optimal power transmission for large-diameter cutters during aggressive machining.

- Effective Thermal Management: A dedicated high-flow cooling system (>16 L/min) effectively manages operational heat, maintaining spindle precision and protecting components during extended production runs.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General Information | Model | A2005701 |

| Housing Diameter | 230 mm | |

| Mounting Orientation | Vertical | |

| Power & Performance | Motor Configuration | Dual Winding (Y/Δ) |

| Rated Power (Y / Δ) | 22 kW (Y) / 26 kW (Δ) | |

| Rated Torque (Y / Δ) | 210 N·m (Y) / 82.7 N·m (Δ) | |

| Maximum Speed | 12,000 rpm | |

| Axial / Radial Stiffness | 500 N/µm / 1000 N/µm | |

| Tool Interface & Drive | Tool Holder | HSK-A100 |

| Compatible Control System | Mitsubishi M800/M80/E80/C80 Series | |

| Encoder | Mitsubishi Serial (GEL244M) | |

| Precision & Construction | Taper Runout | ≤ 2.0 µm @ 25mm |

| Bearing System | 71918 × 4, N1012 × 1 (Grease) | |

| Dynamic Balance | G0.4 | |

| Clamping & Automation | Drawbar Force | 45,000 ± 2,000 N |

| Tool Change Signal | PNP / NO | |

| Cooling Systems | Spindle Body Cooling | Oil/Water Coolant (>16 L/min, >3 kW) |

| Physical Data & Warranty | Net Weight | 157 kg |

| Warranty | 1 Year |

Primary Applications

This high-torque spindle is ideally suited for:

- Heavy-duty vertical milling and roughing of large steel plates, weldments, and castings on gantry mills and large VMCs.

- Machining of large molds, dies, and industrial tooling.

- Manufacturing of structural components for the energy, mining, and heavy machinery sectors.

- Any demanding application on Mitsubishi-controlled machines that requires a reliable blend of high torque and high power.

Value Proposition

The A2005701 offers Mitsubishi users a powerful and intelligent spindle solution that adapts to the task. It combines the peace of mind of certified compatibility with the performance benefits of a dual-winding design, maximizing your machine’s capability, uptime, and return on investment. It is the strategic choice for enhancing productivity and tackling a wider range of heavy workpieces with confidence.

Optimize Your Mitsubishi Machining Center for Heavy-Duty Work. Contact our engineering team to discuss integrating the A2005701 High-Torque Spindle into your vertical machining setup.