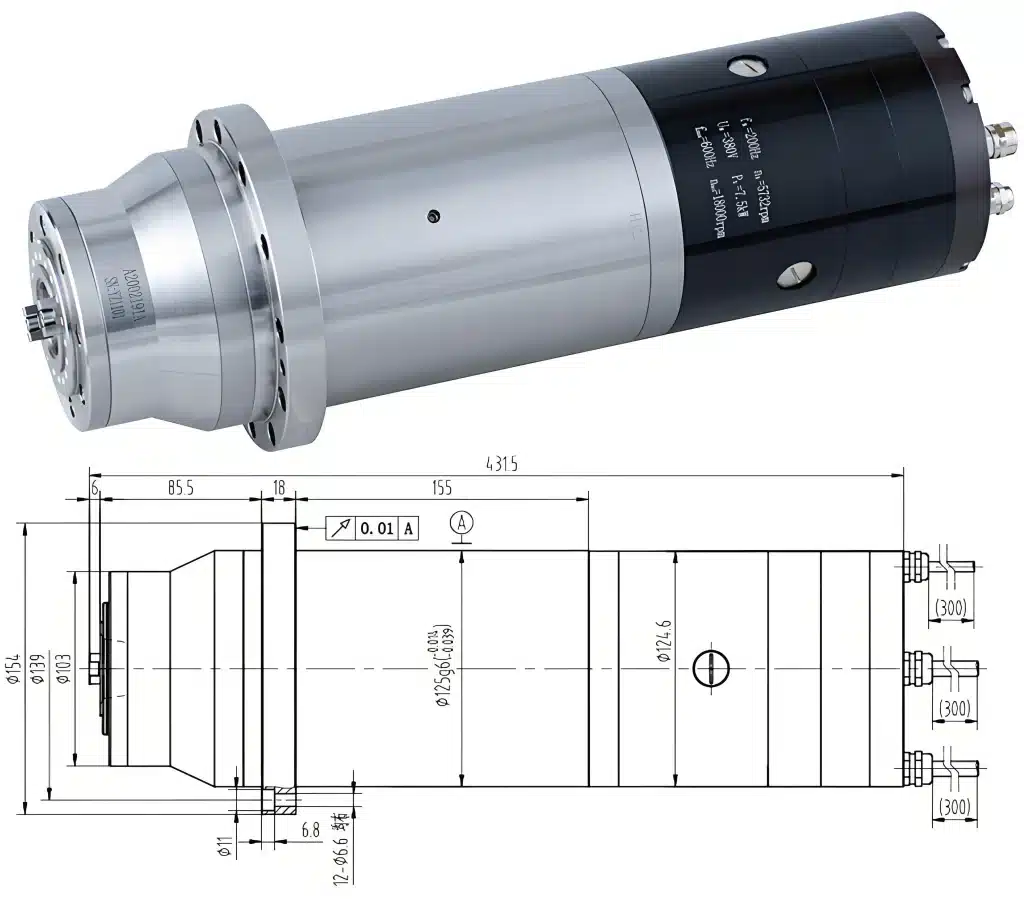

A2005821 High-Power Horizontal Machining Spindle

125mm Siemens Flange | 11 kW Power | Multi-Interface Configurable

The A2005821 is a high-performance, horizontally mounted electric spindle engineered for powerful and precise machining in horizontal machining centers (HMCs) or multi-tasking lathes. Built with a standardized 125mm Siemens flange interface, it delivers robust power (11 kW) and high torque (10 N·m) for demanding milling and drilling operations. Its defining feature is exceptional configuration flexibility, offering a choice of tool holders and encoder types to ensure seamless integration with your machine tool and control system.

Product Overview

Designed for reliable heavy-duty cutting in horizontal applications, this spindle combines high rigidity, substantial torque, and versatile compatibility. The horizontal mounting orientation makes it ideal for multi-sided machining and complex part production. Whether your shop uses HSK, BT, or BBT tooling standards, and whether your control requires high-resolution feedback or sensorless operation, the A2005821 can be configured to match.

Core Features & Advantages

- High Power & Torque for Productivity: 11 kW and 10 N·m of torque provide the force needed for efficient material removal in steel, cast iron, and alloys.

- Exceptional Rigidity & Accuracy: High radial stiffness (300 N/μm) and precise runout tolerances (≤2.0 μm) ensure stability and superior surface finish, even during side-cutting operations in horizontal orientation.

- Unmatched Configuration Flexibility:

- Tool Holder Options: Configure with HSK E50, BBT30, or BT30 to match your existing tooling system.

- Feedback Options: Choose from Sine Wave (128-tooth), Square Wave encoder, or No Encoder for compatibility with your CNC or VFD.

- Standardized Siemens Flange: The 125mm flange adheres to common Siemens-style interface dimensions, simplifying mechanical integration and replacement on many HMCs and machining centers.

- Designed for Horizontal Duty: Specifically engineered for horizontal installation, with appropriate sealing and lubrication for reliable operation in this orientation.

- High Clamping Security: Extremely high drawbar force (8,000 – 10,000 N) ensures tools are held securely under heavy cutting loads.

Detailed Technical Specifications

| Category | Parameter | Specification / Value |

|---|---|---|

| General & Ordering | Spindle Designation | Electric Spindle |

| Model | A2005821 | |

| Mounting Orientation | Horizontal | |

| Spindle Flange | Siemens Standard | |

| Warranty | 1 Year | |

| Performance | Maximum Speed | 27,000 rpm |

| Radial Stiffness | 300 N/µm | |

| Axial Stiffness | 100 N/µm | |

| Taper Runout | ≤ 2.0 µm (at 25mm); ≤ 8.0 µm (at 250mm) | |

| Face Runout | ≤ 2.0 µm | |

| Rated Power | 11 kW | |

| Rated Torque | 10 N·m | |

| Drawbar Force | 8000 – 10000 N | |

| Dynamic Balance Grade | G0.4 | |

| Mechanical Construction | Tool Holder Interface | Customer Selectable: HSK-E50 / BBT30 / BT30 |

| Bearing Specification | 7008 × 2, 71910 × 3 | |

| Lubrication | Grease | |

| Spindle Weight | 25 kg (Packed: 32 kg with wooden case) | |

| Drive Method | Built-in Motor | |

| System Integration (Configurable) | Encoder Signal | Customer Selectable: • Sine Wave / 128-tooth • Square Wave • No Encoder |

| Tool Change Signal | PNP / NO (Normally Open) | |

| Cooling & Pneumatics | Cooling Method | Oil or Water Coolant Flow > 6 L/min, Cooling Power > 1 kW, Max. Inlet Temp 30°C |

| Air Seal Pressure | 2 – 7 bar | |

| Clean Air Pressure | 2 – 7 bar | |

| Tool Release Pressure | 5 – 7 bar | |

| Tool Release Air Volume | 184 cm³ |

Primary Applications

This versatile horizontal spindle is ideal for:

- Multi-face machining on horizontal machining centers (HMCs).

- Complex part production in the automotive, aerospace, and general engineering sectors.

- Heavy-duty milling and boring operations where horizontal spindle access is required.

- Shops seeking a future-proof spindle that can adapt to different tooling standards or control systems.

Configuration & Integration Support

The A2005821 is built to be adapted to your needs. Our technical team will work with you to select the correct tool holder and encoder configuration for a true plug-and-play experience with your horizontal machining center. This flexibility protects your investment and simplifies maintenance and future upgrades.

Configure Your Ideal Horizontal Spindle Solution. Contact us today to discuss your tooling and control requirements and receive a tailored quotation for the versatile A2005821 High-Power Horizontal Spindle.