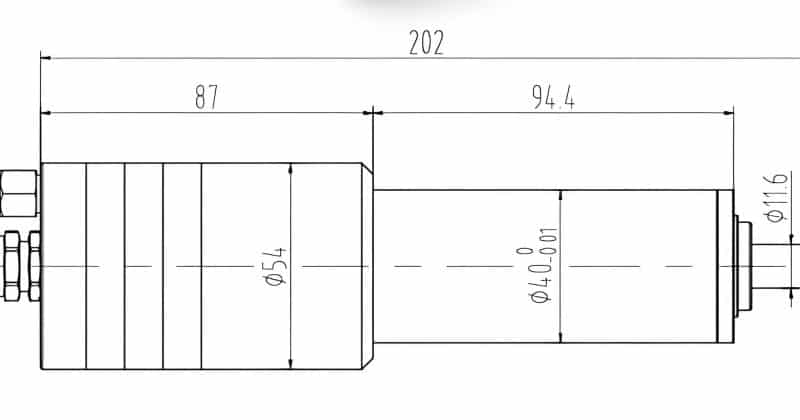

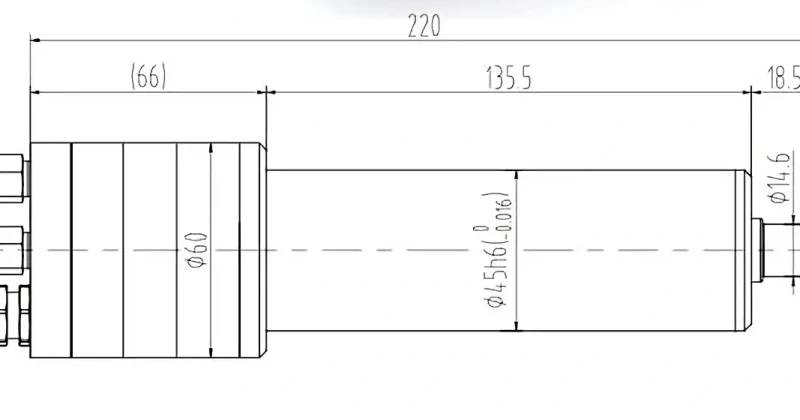

SFG4506-01

High-Precision 45 Series Electric Spindle

Engineered for High-Performance Dental Milling & Precision Micro-Machining

Product Overview

The 45 Series Electric Spindle is a core power component engineered for high-speed, high-precision machining applications, with a specific design focus for dental milling machines. It integrates a 90V single-winding asynchronous motor with a high-precision angular contact bearing system. Within its compact cylindrical form, it delivers an exceptional speed of 60,000 RPM, 0.5kW of power, and outstanding rigidity, making it the ideal solution for the efficient and precise machining of materials like zirconia, resin, and metals.

Key Features & Advantages

Superior Performance: 90V single-winding design achieves both high speed (60,000 rpm) and substantial power (0.5 kW) output, ensuring high processing efficiency.

Exceptional Stability & Rigidity: Utilizes a high-stiffness bearing configuration (Front: 71902×2, Rear: 71902×1) to effectively dampen vibration, guaranteeing machining accuracy and superior surface finish.

High-Efficiency Heat Dissipation: The optimized structure combined with an integrated air-cooling system enables low-heat operation, ensuring thermal stability during prolonged operation and extending service life.

Compact & Lightweight...