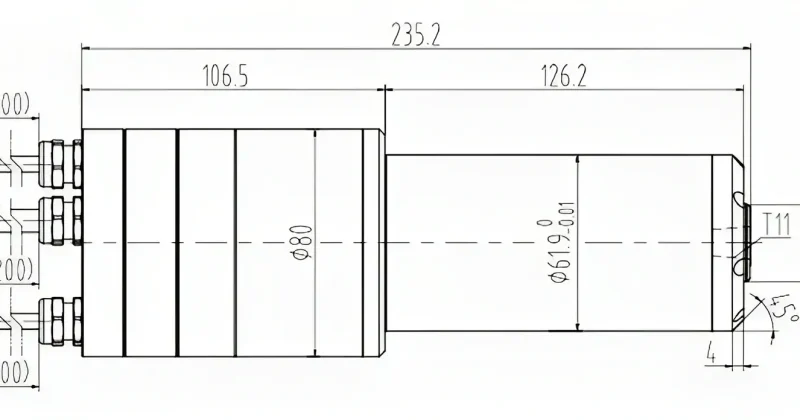

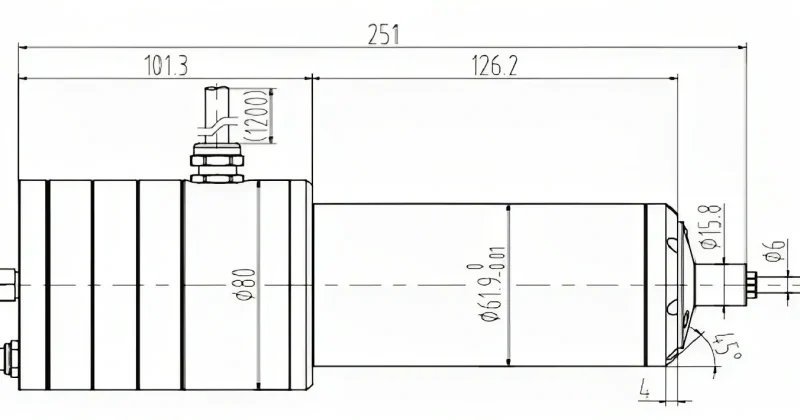

SFG62J-C3A High-Precision Electric Spindle

The Premier Choice for Mirror Finishing & Ultra-Precision Machining

Product Overview

The SFG62J-C3A is a professional-grade 62mm-diameter electric spindle engineered to deliver exceptional surface finishes for High-Gloss Machines (Mirror Surface Machining) and High-Precision Engraving & Milling Centers. Distinguished from its counterparts by its optimized 1.8KW power rating and versatile collet system, this model is purpose-built for applications where flawless surface integrity, supreme accuracy, and flexible tooling are paramount. It achieves the perfect synergy of high speed, thermal stability, and minimal vibration for impeccable results across a wider range of tool sizes.

Key Differentiators & Advantages

Engineered for Flawless Finishes: A lower 1.8KW power profile optimized for finishing operations, coupled with precision-ground components, minimizes vibration and thermal distortion, making it the ideal choice for achieving Ra<0.1μm mirror-like surfaces and intricate micro-details.

Superior Dynamic Precision: Features exceptional rigidity (≥86 N/μm radial, ≥43 N/μm axial) and tightly controlled runout (≤2.0μm static, ≤5.0μm dynamic), ensuring consistent tool engagement and dimensional accuracy critical for 3D engraving and fine finishing.

Versatile Tooling...