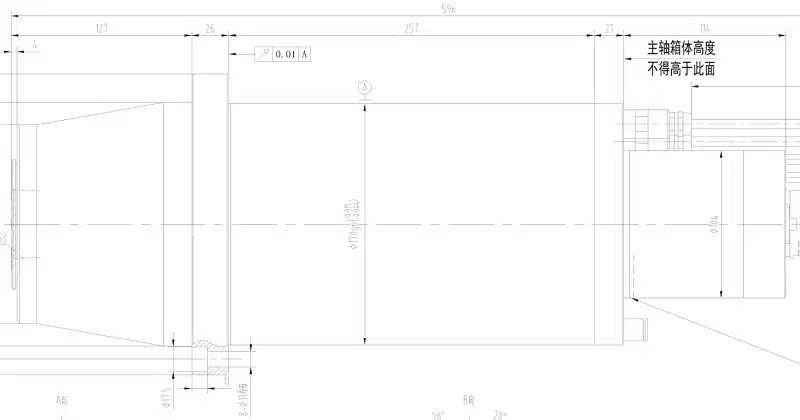

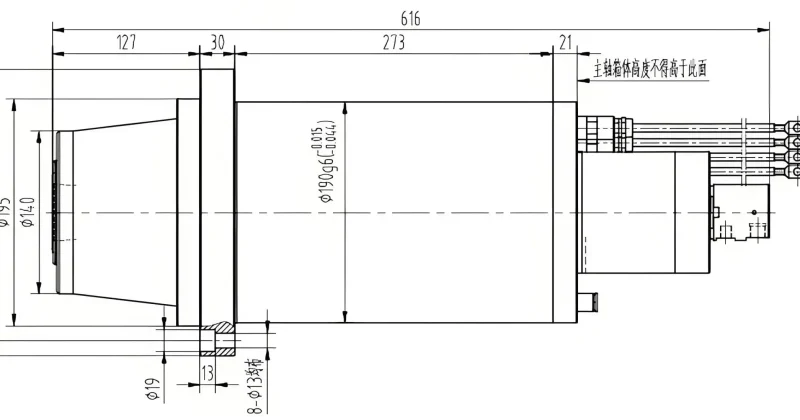

A2004521-190

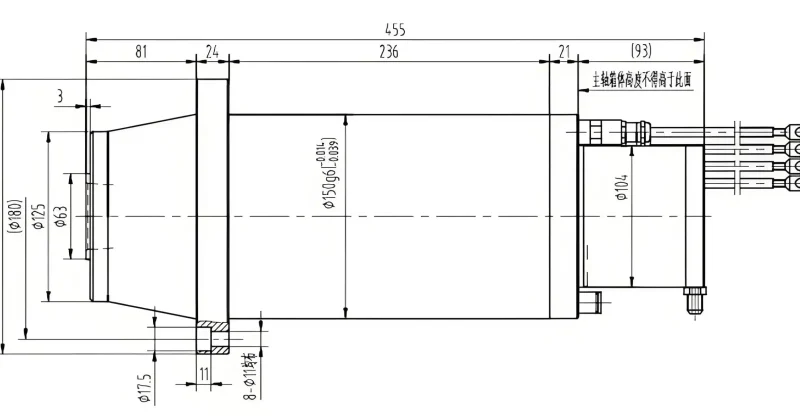

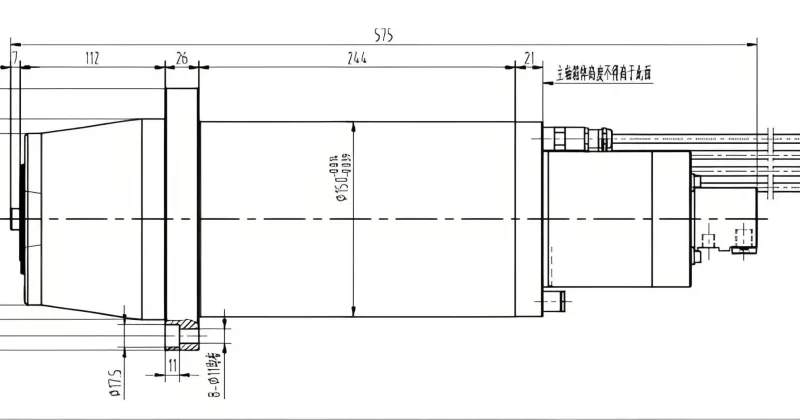

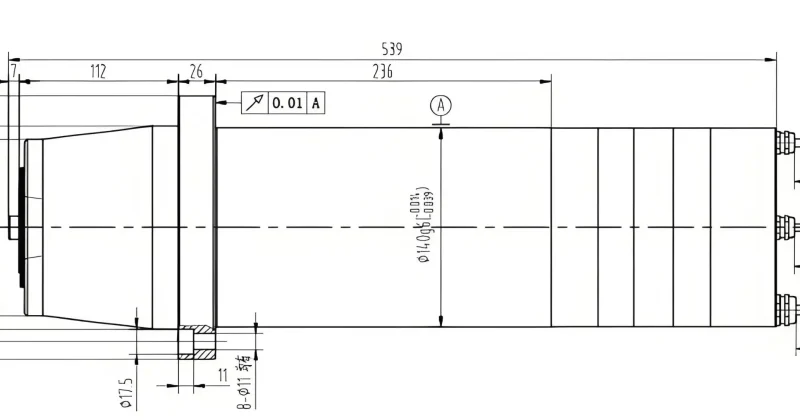

A2004521 High-Torque Dual-Winding Spindle103.8 N·m Torque | 45 kW Power | 190mm HSK-A63 | Dual-Mode Powerhouse for Heavy-Duty Machining

The A2004521 is an exceptional electric spindle engineered to deliver unparalleled versatility and raw cutting force for the most demanding industrial applications. Featuring a robust 190mm diameter and an HSK-A63 tool interface, its core innovation lies in the 400V dual-winding (Y/Δ) motor, offering two distinct operational profiles: an ultra-high torque mode (103.8 N·m) for extreme heavy-duty cutting, and a high-power mode (45 kW) for maximum material removal rates. Designed for vertical installation on large machining centers and gantry mills, and equipped with a 7 MPa through-spindle coolant system, it is the ultimate solution for machining high-strength alloys, large molds, and heavy structural components with supreme efficiency.

Technical Overview

This spindle is built to provide machine shops with strategic flexibility without compromising performance. Its dual-winding architecture allows a single spindle unit to excel in vastly different machining regimes. Whether the priority is conquering the toughest materials with immense torque or maximizing productivity...