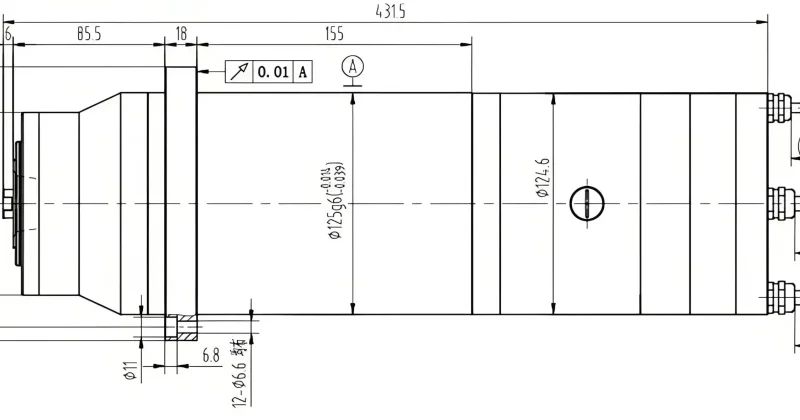

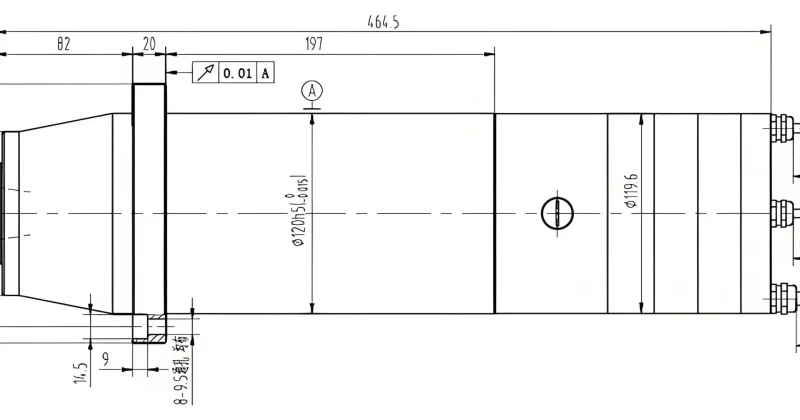

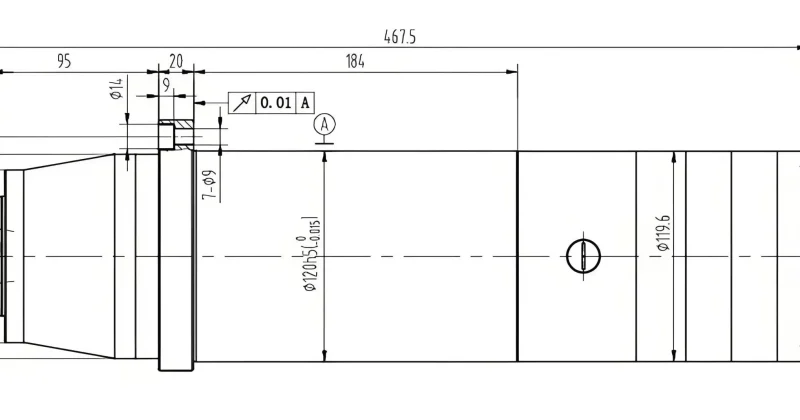

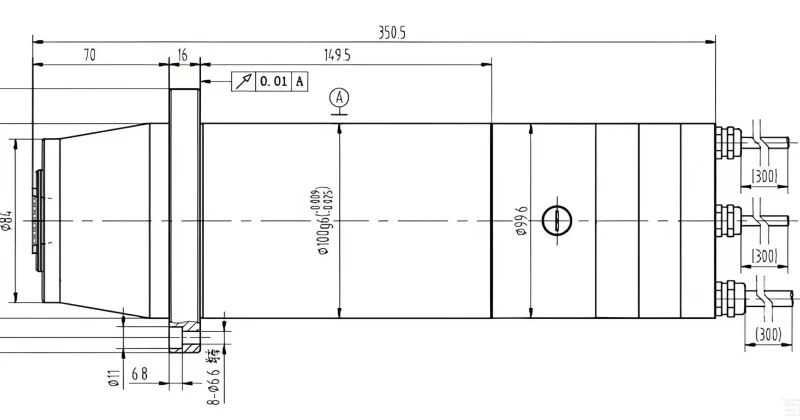

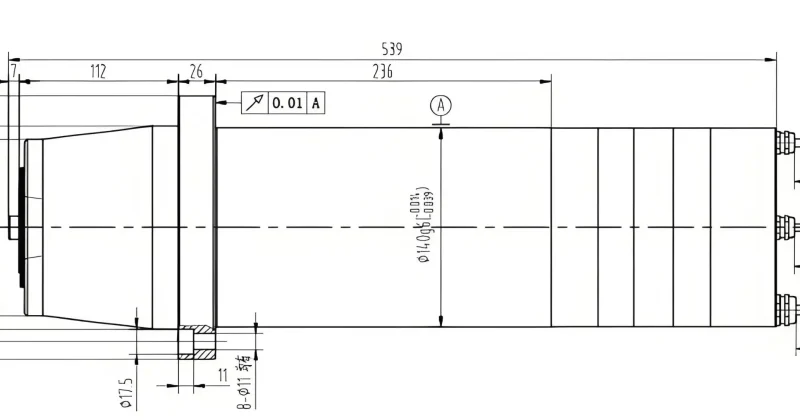

A2003071-140 Y/Δ

A2003071 High-Performance Dual-Mode Spindle for Mitsubishi Systems140mm Diameter | Up to 28.55 N·m Torque | Y/Δ Configuration for Ultimate Machining Versatility

The A2003071 is a premium, high-rigidity electric spindle engineered as a powerhouse for vertical machining centers and precision engraving machines equipped with Mitsubishi CNC controls. Its core innovation is the Y/Δ dual-winding system, allowing a single spindle to operate as both a high-torque heavy-duty unit (28.55 N·m) and a high-power, higher-speed spindle. Combined with exceptional structural stiffness and thermal management, it delivers unmatched adaptability for a vast range of materials and machining strategies.

Technical Overview

Built with a robust 140mm outer diameter, the A2003071 is designed for stability and precision under extreme loads. It seamlessly integrates power with flexibility: choose immense torque for difficult materials or switch to a mode optimized for efficient high-speed machining. Pre-configured for the Mitsubishi ecosystem, it guarantees plug-and-play performance, reliability, and optimal servo control for demanding production environments.

Core Features & Advantages

Dual-Mode Operational Excellence:

Star (Y) Connection: Unleashes 28.55 N·m of massive torque at 6 kW, specifically...