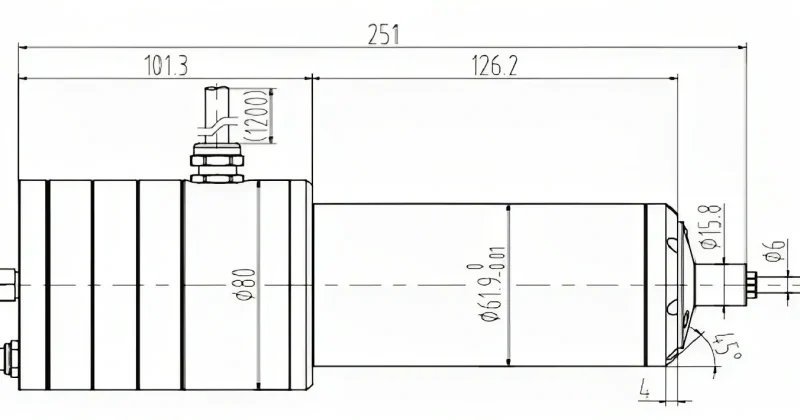

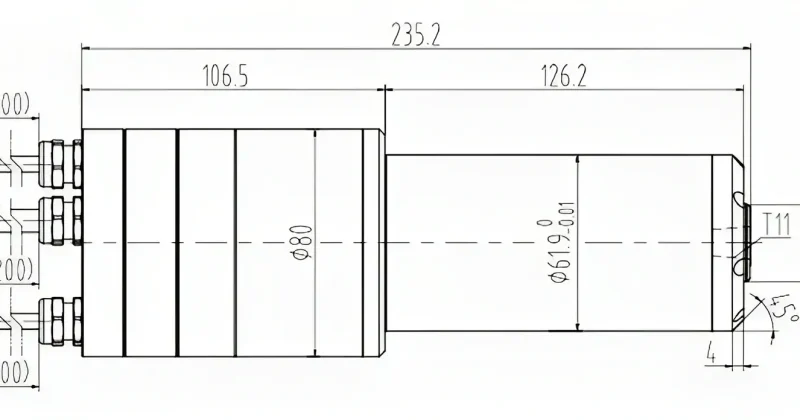

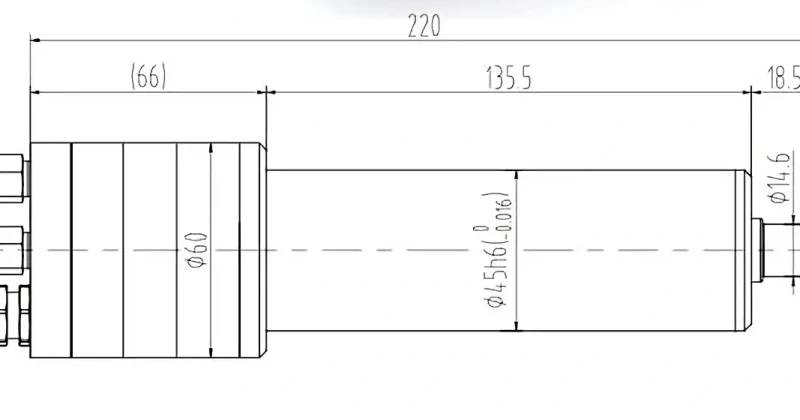

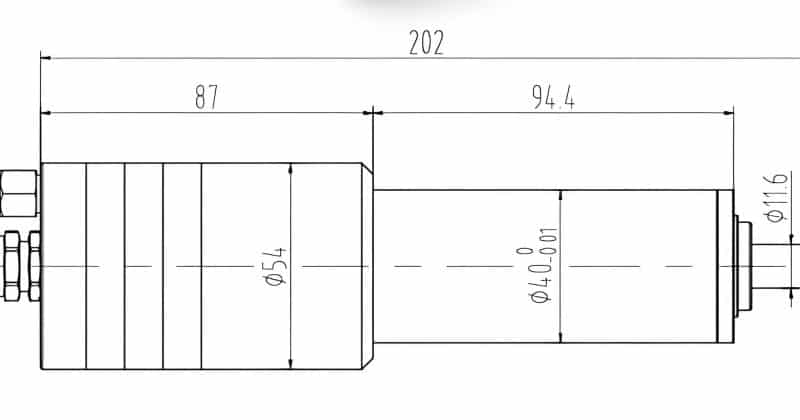

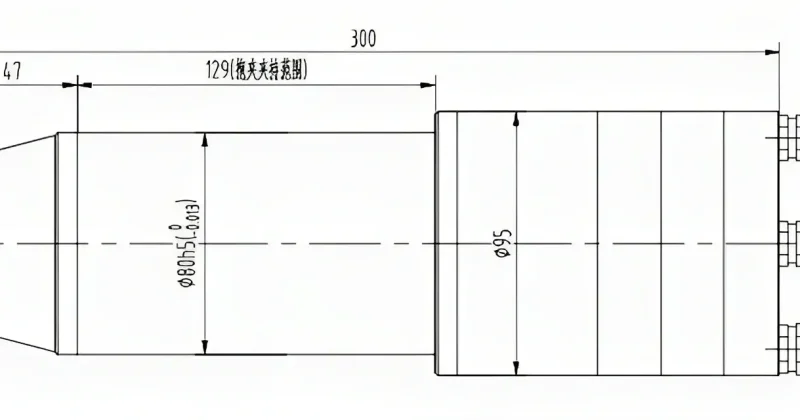

A2003101-80

Model A2003101 High-Precision Milling & Engraving Spindle

Designed for Demanding Machining: Where Speed, Rigidity, and Accuracy Converge

The A2003101 represents a superior-grade electric spindle engineered for high-performance CNC engraving and milling centers. Featuring a robust 80mm outer diameter and a powerful 3.7 kW, 380V single-winding motor, it delivers an exceptional blend of high rotational speed (50,000 RPM) and substantial torque (1.2 N·m). This spindle is built to excel in applications requiring meticulous surface finish, tight tolerances, and efficient material removal across metals, composites, and advanced engineering materials.

Technical Overview & Design Philosophy

Crafted for stability under load, the A2003101 integrates a high-rigidity mechanical design with precision components. The utilization of four matched sets of 71905 precision angular contact ball bearings, combined with permanent grease lubrication, forms the foundation for its high stiffness, extended service life, and remarkably smooth operation. Its G0.4 dynamic balance grade ensures minimal vibration at high speeds, which is critical for achieving superior surface quality and protecting machine tool integrity. Designed for vertical installation, it...