The Premier Choice for Mirror Finishing & Ultra-Precision Machining

Product Overview

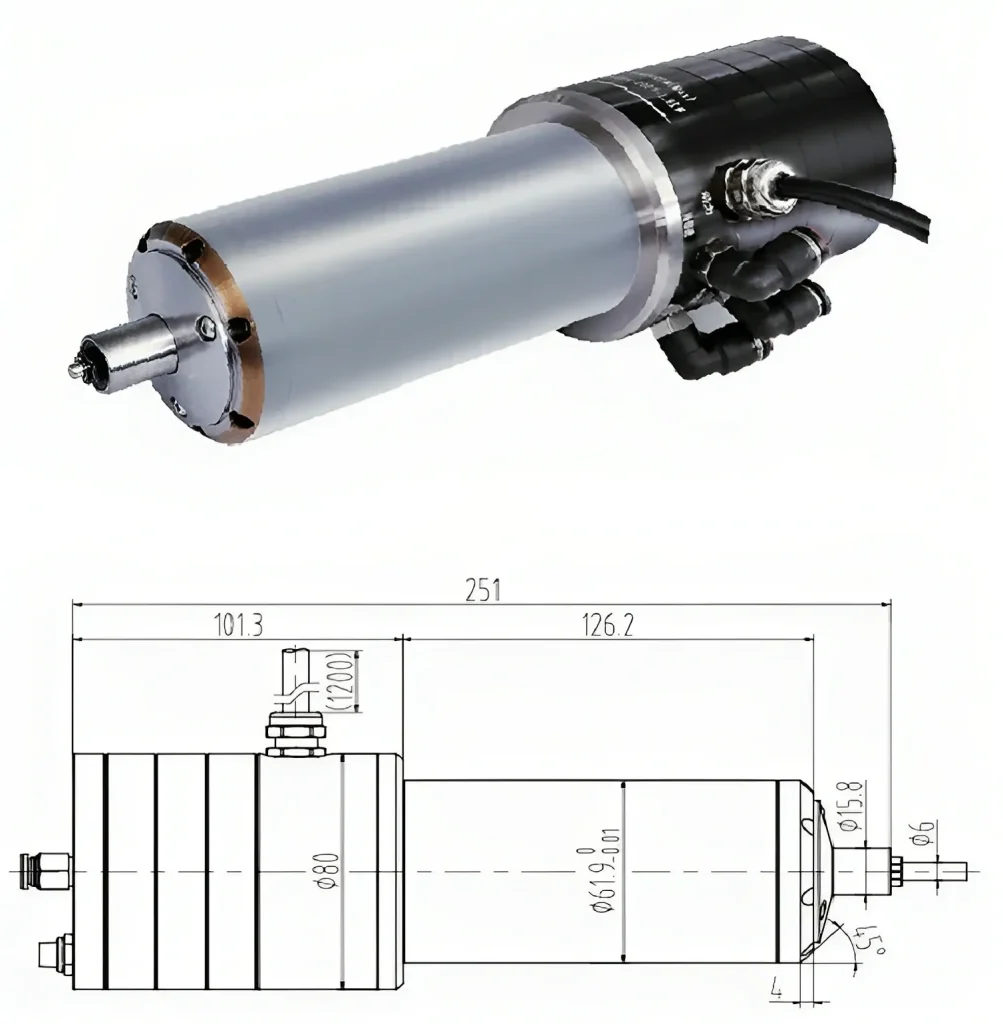

The SFG62J-C3A is a professional-grade 62mm-diameter electric spindle engineered to deliver exceptional surface finishes for High-Gloss Machines (Mirror Surface Machining) and High-Precision Engraving & Milling Centers. Distinguished from its counterparts by its optimized 1.8KW power rating and versatile collet system, this model is purpose-built for applications where flawless surface integrity, supreme accuracy, and flexible tooling are paramount. It achieves the perfect synergy of high speed, thermal stability, and minimal vibration for impeccable results across a wider range of tool sizes.

Key Differentiators & Advantages

- Engineered for Flawless Finishes: A lower 1.8KW power profile optimized for finishing operations, coupled with precision-ground components, minimizes vibration and thermal distortion, making it the ideal choice for achieving Ra<0.1μm mirror-like surfaces and intricate micro-details.

- Superior Dynamic Precision: Features exceptional rigidity (≥86 N/μm radial, ≥43 N/μm axial) and tightly controlled runout (≤2.0μm static, ≤5.0μm dynamic), ensuring consistent tool engagement and dimensional accuracy critical for 3D engraving and fine finishing.

- Versatile Tooling Compatibility: Offers enhanced flexibility by supporting interchangeable straight-shank collets for φ3.175mm, φ4mm, and φ6mm tool diameters. This allows operators to adapt quickly to different machining requirements without changing the spindle. The clamping system provides a secure grip with a torque of ≥200 N·cm.

- Optimized Thermal & Contamination Control: An integrated high-efficiency water-cooling circuit (≥1.3 L/min) ensures outstanding thermal stability. The air seal function (0.2-0.7 MPa) effectively protects critical internal components from coolant and abrasive debris, guaranteeing long-term reliability.

Detailed Technical Specifications

| Category | Parameter | Specification |

|---|---|---|

| Basic Specifications | Model | SFG62J-C3A |

| Motor Type | Asynchronous Induction (2-Pole) | |

| Max. Frequency / Speed | 1000 Hz / 60,000 rpm | |

| Rated Voltage / Current | 200 V / 6.3 A | |

| Rated Power / Torque | 1.8 kW / 0.29 N·m | |

| Tool Holder / Collets | Interchangeable Straight-Shank Collets for φ3.175, φ4, φ6 mm | |

| Tool Change Method | Pneumatic | |

| Weight | 4.3 kg | |

| Performance Metrics | Cylinder Pressure | 0.5 – 0.7 MPa |

| Clamping Torque | ≥200 N·cm (for φ3.175 shank) | |

| Static Runout (16mm from nose) | ≤ 2.0 μm | |

| Dynamic Runout | ≤ 5.0 μm | |

| Vibration Velocity | ≤ 0.8 mm/s | |

| Radial Stiffness | ≥ 86 N/μm | |

| Axial Stiffness | ≥ 43 N/μm | |

| Noise Level | ≤ 70 dBA | |

| Interface & Requirements | Mounting Diameter | φ61.9<sub>-0.01</sub><sup>0</sup> mm |

| Coolant Water Flow (@0.25MPa) | ≥ 1.3 L/min | |

| Air Seal Pressure | 0.2 – 0.7 MPa | |

| Motor Winding Withstand Voltage | 1200 V/min |

Primary Applications

- Ultra-High Gloss (Mirror) Machining: Final finishing of consumer electronics casings, automotive interior trims, luxury appliance surfaces, and mold cavities requiring a perfect reflective finish.

- Precision Micro-Engraving & 3D Texturing: Fine detail engraving, logo marking, and complex 3D texture creation on molds, dies, and premium consumer products.

- High-Precision Milling of Small Components: Machining of intricate parts for the medical, optical, and watchmaking industries, with the flexibility to use a range of small-diameter tools.

Why Choose the SFG62J-C3A?

✅ Purpose-Built for Perfection: Optimized power specifically for high-gloss finishing and micro-engraving.

✅ Guaranteed Accuracy: Exceptional stiffness and ultra-low runout specifications ensure repeatable, high-precision results.

✅ Enhanced Flexibility: The ability to use φ3.175,, φ4, and φ6mm tools with interchangeable collets provides unmatched versatility for various operations, from fine engraving to light milling.

✅ Reliable & Robust Design: Effective cooling and sealing ensure stable, long-term performance in demanding production environments.

The SFG62J-C3A is engineered for applications where surface finish and tooling flexibility are critical. Contact us for integration support, 2D/3D models, and information on collet kits.